Views: 0 Author: Site Editor Publish Time: 2025-09-19 Origin: Site

You rely on the mvr evaporator as a high-efficiency solution that transforms how your industry manages energy, environmental management, and sustainability mandates. The mvr process compresses vapor, reusing it as a heat source for the evaporator. This approach maximizes energy efficiency and supports sustainable practices. Across sectors, mvr technology drives energy recovery initiatives and reduces primary energy use by up to 41% in wastewater treatment. The global market has grown rapidly, fueled by demand in food, pharmaceuticals, and environmental management.

Market size in 2024: USD 1,052.54 million

Projected to reach USD 1,883.89 million by 2033

You rely on the compressor as the driving force behind the mvr tubular thin film evaporator. This component compresses steam, raising its temperature and pressure. The process allows the mvr tubular thin film evaporator to recycle vapor, which reduces your energy costs and carbon emissions. When you compare mvr tubular thin film evaporator systems to traditional evaporators, you see dramatic improvements:

| Metric | MVR Evaporators | Traditional Evaporators |

|---|---|---|

| Energy Usage Reduction | Up to 90% | Higher energy consumption |

| Operational Cost Efficiency | Lower operational costs | Higher operational costs |

| Carbon Emissions | Significantly lower | Higher emissions |

You can choose from several compressor types for your mvr tubular thin film evaporator, including turbo compressors, gearbox types, direct-drive models, pipeline pressurized turbo compressors, Roots steam compressors, ordinary centrifugal steam compressors, and single-stage high-speed centrifugal compression blowers. Each type offers unique benefits for different applications.

Heat exchangers in your mvr tubular thin film evaporator optimize heat transfer. You benefit from faster evaporation rates and improved system efficiency. Corrugated tubes create turbulence, which reduces fouling and boosts performance. For high-fouling materials, you might select scraped surface heat exchangers, such as the HRS Unicus Series. The choice of material matters:

| Property | Description |

|---|---|

| Corrosion Resistance | Handles aggressive fluids in wastewater or chlor-alkali applications. |

| Thermal Stability | Performs well under extreme temperatures, such as in lithium extraction. |

| Durability | Lowers maintenance needs and extends lifespan. |

| Robust Construction | Duplex stainless steel resists corrosion and wear. |

Separators and crystallizers in your mvr tubular thin film evaporator system play a vital role in product quality. These components efficiently separate and crystallize materials during evaporation. The gentle operation of the mvr tubular thin film evaporator preserves essential characteristics, such as flavor and nutritional value, which leads to higher product purity.

Modern mvr tubular thin film evaporator systems use advanced control systems. You gain precise regulation of pressure, temperature, and flow. Features include PLC or DCS systems, automatic cleaning, and shutdown operations with alarms for system protection.

| Feature | Description |

|---|---|

| Control Cabinets | Regulate pressure, temperature, and compression ratio for automation. |

| Control System | PLC/DCS for compressor speed, valves, flowmeters, temperature, and pressure. |

| Automatic Operations | Includes automatic evaporation, cleaning, and shutdown with alarms and protection. |

Smart automation features, such as real-time monitoring and automated control loops, help you maintain optimal evaporation parameters. These systems minimize manual oversight and maximize efficiency in your mvr tubular thin film evaporator operations.

You see Tier 1 manufacturers leading the mvr falling film evaporator market with advanced solutions and global reach. These companies deliver end-to-end systems for large-scale industry projects, including zero liquid discharge and high-salinity wastewater treatment. You benefit from their expertise in integrating mvr tubular thin film evaporator technology with robust automation and compliance features. The top five manufacturers—Howden, Piller, GEA, Suez, and Chongqing Jiangjin—hold over 30% of the global market share. You find their presence strongest in regions such as North America and Europe, where infrastructure and regulatory standards drive innovation. The Asia-Pacific region, especially China, India, and South Korea, shows rapid expansion due to urbanization and manufacturing scalability.

You can find major mvr evaporator manufacturers in:

Netherlands

South Africa

Italy

Malaysia

Brazil

Mexico

Spain

Argentina

Saudi Arabia

Germany

France

UK

You rely on Tier 2 manufacturers for specialized mvr tubular thin film evaporator designs tailored to niche industry needs. These companies focus on innovation, offering unique features for food, pharma, and biotech sectors. You benefit from their advanced coatings, hybrid systems, and AI-driven automation. The table below highlights key innovation strategies:

| Innovation Strategy | Description | Benefits |

|---|---|---|

| Silica-based hydrophilic coatings | Reduces fouling rates in dairy evaporation plants | Reduces cleaning downtime by 30% |

| Graphene-Coated Heat Exchange Tubes | High thermal conductivity and compact design | Reduces surface area by 20% |

| Mechanical Vapor Recompression (MVR) | Variable speed compressors | Reduces steam consumption by 40-60% |

| Organic Rankine Cycle (ORC) | Heat recovery integration | Improves overall plant efficiency by 10-15% |

| AI-driven automation | Real-time monitoring and predictive analytics | Improves maintenance efficiency |

| Hybrid Multi-Effect & Membrane Distillation Systems | Integrates evaporation with membrane separation | Achieves 95% water recovery in ZLD |

| Solar Thermal Integration | Reduces fossil fuel consumption | Energy consumption reduced by 30-50% |

You see these manufacturers driving the mvr falling film evaporator market forward with new materials and smart controls.

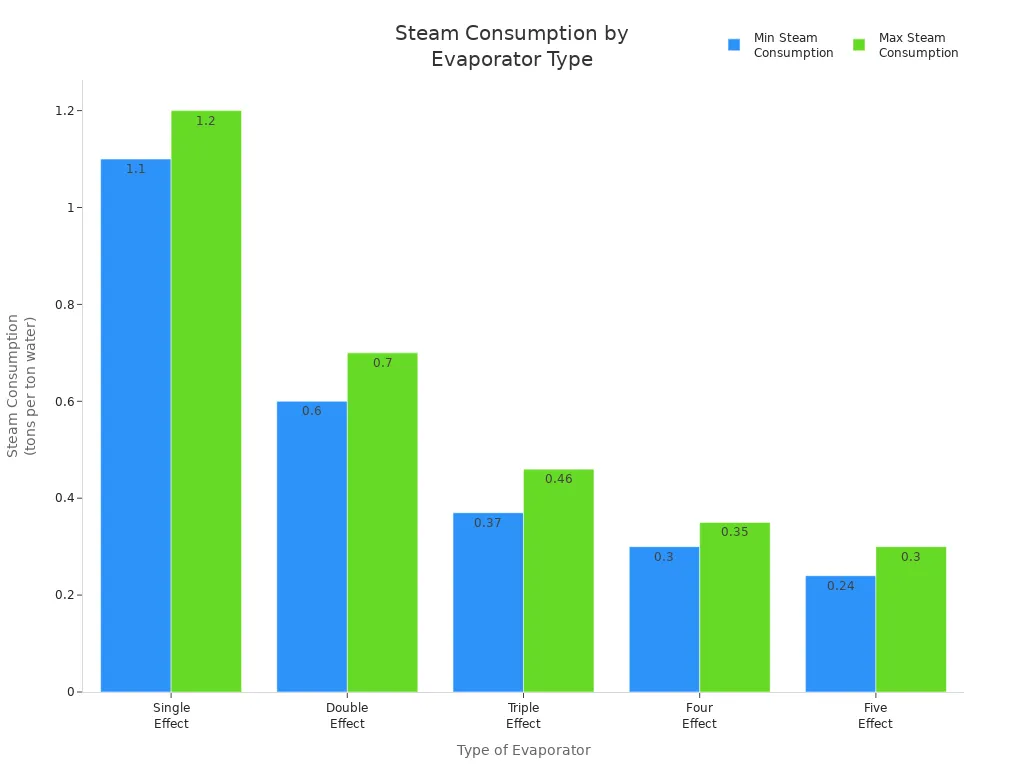

You turn to Tier 3 manufacturers for cost-effective mvr tubular thin film evaporator solutions. These suppliers focus on affordability and operational efficiency, serving mid-sized industry projects and emerging markets. You notice their systems use multi-effect evaporator designs to minimize steam consumption and reduce costs. The CALORIS CONCENTRIX® mvr evaporator, for example, uses an electrically driven turbofan motor, which helps maintain balanced heat operation and lowers the need for cooling water. This approach proves valuable in regions with limited water resources.

You see the mvr falling film evaporator market evolving as Tier 3 suppliers optimize costs and expand access to efficient evaporator technology across the industry.

You see the mvr falling film evaporator market expanding rapidly as industries seek greater energy efficiency and sustainability. The mvr tubular thin film evaporator stands out in several sectors, each with unique opportunities and application developments.

You rely on the mvr tubular thin film evaporator to concentrate juices, dairy, and other food products. This technology preserves flavor and nutrients while reducing energy use. The mvr falling film evaporator market in this sector grows as you look for compact systems that fit limited spaces. You benefit from lower operating costs and improved product quality. The table below highlights key benefits:

| Benefit | Description |

|---|---|

| Energy Efficiency | Reduces energy use by up to 90% |

| Improved Product Quality | Preserves flavor, color, and nutrients |

| Space Efficiency | Compact design lowers facility costs |

| Low Maintenance | Fewer moving parts mean less downtime |

You also notice opportunities for water conservation and reduced carbon emissions, which align with your sustainability goals.

You use the mvr tubular thin film evaporator to treat challenging high-salt wastewater. This application supports zero-liquid discharge by separating salts and enabling water reuse. The mvr falling film evaporator market in wastewater treatment grows as you face stricter regulations and rising water scarcity. You achieve high separation efficiency and resource recovery, making this technology essential for your operations.

You depend on the mvr tubular thin film evaporator for pharmaceutical and food processing. This application ensures product purity and protects sensitive ingredients. You remove impurities and concentrate active components without damaging them. The mvr falling film evaporator market in pharma and biotech offers opportunities for manufacturers to deliver systems that meet strict quality standards and regulatory requirements.

You see new opportunities in lithium battery recycling and seawater desalination. The mvr tubular thin film evaporator helps recover valuable metals and purify water. Manufacturers innovate with selective lithium extraction and membrane-based separation. The mvr falling film evaporator market in these sectors grows as you seek efficient, sustainable solutions for resource recovery and clean water.

Insights from recent market trends show that the mvr evaporator supports a wide range of industry applications, creating new opportunities for manufacturers and driving the market forward.

| Industry Sector | Description |

|---|---|

| Food & Beverage | Concentration and purification of food products |

| Wastewater | Cleans factory wastewater and recovers useful materials |

| Lithium | Recovers metals for battery production |

| Medical | Purifies and concentrates pharmaceutical ingredients |

You face several risks in the mvr falling film evaporator market. Supply chain disruptions can impact your ability to source critical components for your evaporator systems. Delays in compressor shipments or fluctuations in steel prices may slow down your projects. Manufacturers often depend on specialized suppliers for high-grade materials and advanced automation hardware. You must monitor global logistics and regulatory changes that affect the industry.

You encounter challenges such as:

Extended lead times for high-end bearings and compressors.

Volatility in raw material costs, especially stainless steel and titanium.

Regional differences in technological adoption and infrastructure.

Limited access to skilled technicians for installation and maintenance.

Regulatory shifts that require rapid adaptation in application standards.

These risks can influence your market position and create opportunities for innovation. You need to stay agile and seek reliable partners in the mvr evaporator supply chain.

You see manufacturers responding to supply chain challenges with new technological solutions. The mvr falling film evaporator market benefits from innovations that improve reliability and efficiency. You gain insights into how automation and smart controls transform your operations.

Recent advancements include:

Improved energy efficiency through latent heat recycling.

Enhanced automation with integrated sensors and IoT connectivity.

Increased process reliability using AI-driven predictive maintenance.

Real-time monitoring for faster response to operational issues.

You can review the latest innovations in the mvr evaporator industry in the table below:

| Innovation Type | Description |

|---|---|

| Energy Efficiency | MVR technology recycles latent heat, optimizing energy use compared to traditional methods. |

| Compressor Design | New efficient compressor designs improve power consumption and handle a wider range of vapor flow. |

| Intelligent Control | Advanced control systems adjust operations based on real-time data, optimizing energy consumption. |

| Material Science | Use of high-grade stainless steels and advanced coatings enhances durability and corrosion resistance. |

| Automation | Integration of sensors and IoT technology allows for remote monitoring and automated operations. |

You discover new opportunities for application in food, wastewater, and emerging sectors. These insights help you make informed decisions and strengthen your position in the mvr falling film evaporator market.

You see the mvr evaporator industry entering a new phase of growth. The market outlook shows strong expansion in water treatment, food processing, and chemical manufacturing. You notice that arid regions now rely on mvr systems for desalination and resource recovery. Governments support these applications with subsidies and environmental mandates. You find future opportunities in replacing aging infrastructure, which creates recurring demand for advanced evaporator systems. The shift from conventional evaporators to mvr technology brings long-term cost benefits and improved sustainability. You observe that workforce capability is rising, with more training programs and awareness in the industry. Research partnerships between manufacturers and institutions drive innovation and open new application fields.

You gain valuable insights as digital monitoring systems become standard, helping you optimize process efficiency and reduce energy consumption.

You benefit from rapid technological adoption in the mvr market. The mvr evaporator system uses steam compressor technology to lower energy use and environmental impact. You see compact and modular evaporator designs that fit diverse industry needs. Digital monitoring and automation improve reliability and process control. You find that sector adoption increases in food, pharma, and chemical applications due to strict hygiene standards.

Here is a summary of key technological advancements shaping the future outlook for mvr evaporators:

| Technological Advancement | Description |

|---|---|

| Energy Conservation | Focus on sustainable manufacturing and reduced energy consumption. |

| Digital Monitoring Systems | Real-time process optimization and efficiency. |

| Innovations in System Design | Compact, modular evaporator systems for flexible installation. |

| Expansion in Applications | Growth in water treatment and desalination across arid regions. |

| Government Support | Subsidies and mandates encourage adoption of mvr technology. |

| Workforce Capability | Training programs enhance skills in the industry. |

| Sector Adoption | Food, pharma, and chemical industries adopt mvr for hygiene and efficiency. |

| Shift to MVR Systems | Replacement of conventional evaporators for cost and sustainability gains. |

| Research Partnerships | Collaboration drives innovation and new application insights. |

| Aging Infrastructure Demand | Recurring market demand for system upgrades. |

You see the mvr evaporator industry evolving with new technologies, expanding applications, and future opportunities for sustainable growth.

You see the mvr evaporator transforming your industry with energy-efficient solutions and advanced automation. The mvr system reduces steam usage, lowers operational costs, and supports strict environmental regulations. You benefit from improved product quality and extended equipment lifespan in every application. The market outlook shows strong growth, driven by demand for sustainable technologies in food, pharma, and high-salinity wastewater treatment. You can expect the market to reach USD 4.8 billion by 2032. The future of mvr technology promises smarter control systems and broader application across global industries.

You see the greatest impact in food processing, pharmaceuticals, chemical manufacturing, and wastewater treatment. These sectors rely on MVR evaporators to reduce energy costs, recover resources, and meet strict environmental standards.

You use MVR technology to recycle vapor as a heat source. This process lowers energy consumption by up to 90% compared to traditional evaporators. You achieve significant savings on operational costs and reduce your carbon footprint.

You perform routine inspections of compressors, heat exchangers, and control systems. Automated cleaning features and predictive maintenance tools help you minimize downtime and extend equipment lifespan.

You can request tailored designs to match your process requirements. Manufacturers offer modular systems, material options, and advanced automation to fit your industry needs.

You face risks such as delays in compressor shipments, fluctuations in raw material prices, and limited access to skilled technicians. Monitoring global logistics and partnering with reliable suppliers helps you manage these challenges.