Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

As global environmental regulations tighten, industries are under increasing pressure to handle hazardous liquid waste responsibly while controlling operational costs and achieving sustainability goals. Traditional disposal or single-step treatment methods for hazardous liquids, especially high-salinity, high-chemical-content wastewater, are often energy-intensive, costly, and environmentally risky. Multi-effect Evaporation & Crystallization has emerged as a compliant, efficient, and scalable technology for the treatment of hazardous liquid waste across industries including chemical manufacturing, pharmaceuticals, metallurgy, and battery production. By enabling high water recovery, salt and resource crystallization, and volume reduction, Multi-effect Evaporation & Crystallization helps industries move toward Zero Liquid Discharge (ZLD) while complying with local and international environmental standards.

ZheJiang VNOR Environmental Protection Technology Co., Ltd. specializes in designing, manufacturing, and installing advanced Multi-effect Evaporation & Crystallization systems, providing industries with proven solutions for sustainable hazardous liquid waste management. This in-depth article explores how Multi-effect Evaporation & Crystallization is applied in compliant hazardous liquid treatment, its operational principles, benefits, challenges, and how it compares to other treatment methods.

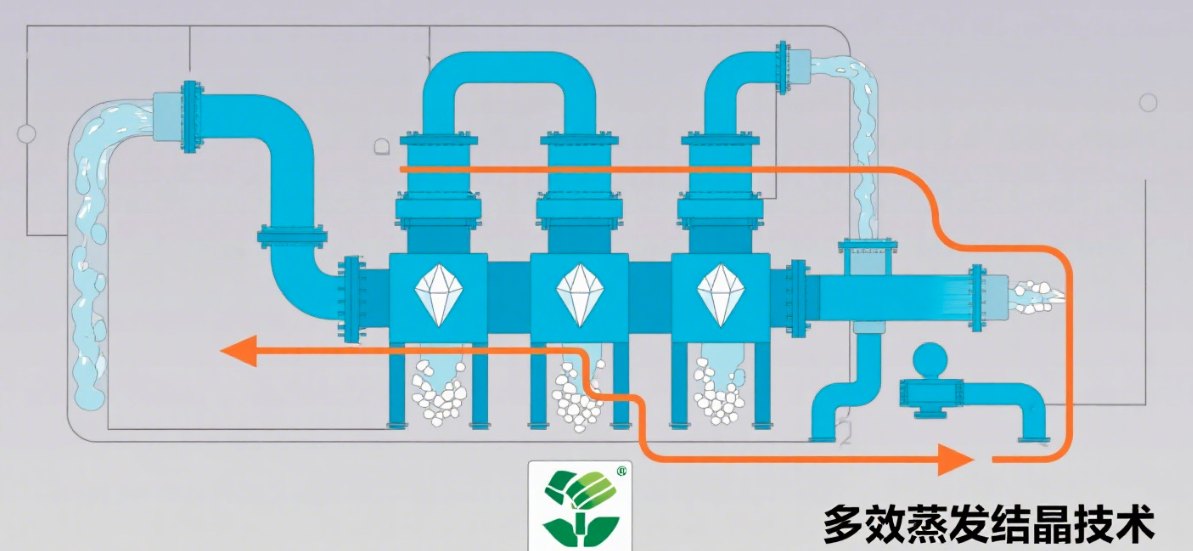

Uses multiple evaporation stages under progressively lower pressures and temperatures. This staged approach allows for efficient energy utilization and effective concentration of the wastewater.

Reuses vapor generated in one effect to heat the next, significantly reducing steam consumption. By cascading the vapor from one stage to the next, the technology achieves remarkable energy savings compared to single-stage evaporation processes.

Concentrates the wastewater until crystallization of salts and contaminants occurs, enabling effective separation and volume reduction. As the wastewater becomes more concentrated, salts and other contaminants crystallize out, allowing for their separation and reducing the overall volume of waste.

Recover clean water for reuse. The process aims to reclaim a high percentage of water from the wastewater, making it suitable for reuse in industrial processes and reducing the need for fresh water.

Crystallize and separate salts, metals, and minerals for safe disposal or recovery. By crystallizing these components, the technology facilitates their removal and potential recovery, ensuring safe disposal and minimizing environmental impact.

Achieve near or full Zero Liquid Discharge. The ultimate goal is to minimize or eliminate liquid waste discharge, supporting sustainable industrial operations.

Ensure compliance with hazardous waste disposal regulations. By effectively treating hazardous liquids and reducing their volume, the technology helps industries meet stringent environmental standards.

Achieves 92–95% water recovery, enabling water reuse within industrial processes while reducing dependence on fresh water resources. This high recovery rate is crucial for industries looking to conserve water and lower operational costs.

Crystallizes hazardous salts, heavy metals, and other solids, reducing the volume of hazardous waste to be handled. This crystallization process not only minimizes waste but also allows for the potential recovery of valuable materials.

Compared to single-effect evaporation, Multi-effect Evaporation & Crystallization reduces steam consumption by up to 80% through vapor reuse, minimizing operational energy costs. This significant reduction in energy use makes the technology highly cost-effective and environmentally friendly.

Systems can be customized for various hazardous liquid waste streams, including those with fluctuating compositions. This flexibility ensures that the technology can be adapted to meet the specific needs of different industrial applications.

Supports Zero Liquid Discharge (ZLD) goals, aligning with environmental regulations while reducing environmental risks. By minimizing or eliminating liquid waste discharge, the technology helps industries meet stringent environmental standards and operate more sustainably.

| Parameter | Multi-effect Evaporation & Crystallization | Incineration | Reverse Osmosis | Chemical Precipitation |

|---|---|---|---|---|

| Water Recovery | 92–95% | None | 70–85% | None |

| Salt/Metal Recovery | Yes | No | Limited | Yes (sludge form) |

| Energy Consumption | Moderate (lower steam usage) | Very High | Moderate to High | Low |

| Residue Volume | Crystals, low volume | Ash, low volume | Concentrate brine | Sludge, moderate volume |

| Compliance with ZLD | Yes | No | Partial | No |

| Suitability for High Salinity | Excellent | N/A | Poor | N/A |

| Operational Complexity | Moderate | High | Moderate | Low |

| Environmental Impact | Low | Air emissions | Membrane disposal | Sludge disposal |

Multi-effect Evaporation & Crystallization provides the best balance of water recovery, contaminant crystallization, and operational efficiency, making it superior for compliant hazardous liquid treatment.

Treating high-salinity, high-chemical-content wastewater with efficient salt recovery while achieving water reuse. This technology is crucial for industries that generate complex wastewater streams, enabling them to recover valuable salts and minimize environmental impact while ensuring regulatory compliance.

Recovering lithium salts and water from brine streams during production and recycling processes. Multi-effect Evaporation & Crystallization plays a vital role in the sustainable production of lithium batteries by efficiently recovering valuable lithium salts and reducing water consumption.

Crystallizing heavy metals for recovery or safe disposal while reclaiming water for reuse. This application helps industries manage hazardous waste streams effectively, ensuring safe disposal or recovery of heavy metals and reducing the environmental footprint of their operations.

Treating waste streams with ammonium, sodium, or sulfate salts to reduce environmental risks and meet discharge regulations. Multi-effect Evaporation & Crystallization is particularly effective in handling these challenging waste streams, enabling industries to achieve zero liquid discharge (ZLD) and minimize environmental risks.

By utilizing Multi-effect Evaporation & Crystallization, industries can:

Reduce hazardous waste disposal volumes, minimizing the environmental impact of their operations.

Recover and reuse water, reducing freshwater consumption and promoting sustainable water management.

Lower carbon emissions through energy-efficient operation, contributing to climate action goals.

Recover valuable resources, supporting circular economy goals and resource optimization.

Ensure environmental compliance while improving sustainability reporting, enhancing corporate responsibility and stakeholder trust.

A: This technology is crucial for treating high-salinity, high-chemical-content wastewater. It enables high water recovery rates (92–95%), effective crystallization of contaminants, and significant reduction in hazardous waste volumes. It supports Zero Liquid Discharge (ZLD) goals and ensures compliance with stringent environmental regulations.

A: Industries such as pharmaceuticals, chemicals, lithium battery manufacturing, metal plating, and surface treatment can benefit significantly from this technology. These sectors often generate complex wastewater streams that require efficient treatment and resource recovery.

A: By using multiple evaporation stages and reusing vapor from one stage to heat the next, the technology achieves high water recovery rates (92–95%). This allows industries to reuse water within their processes, reducing dependence on fresh water resources.

A: Crystallizing contaminants reduces the volume of hazardous waste to be handled and enables the recovery of valuable salts and metals. This not only minimizes environmental impact but also supports resource optimization and circular economy goals.

A: Compared to Incineration, Multi-effect Evaporation & Crystallization is more energy-efficient and produces low-volume crystalline residues. Compared to Reverse Osmosis, it achieves higher water recovery rates (92–95% vs. 70–85%) and is more effective for high-salinity wastewater. It also supports ZLD goals and is more environmentally friendly.

Multi-effect Evaporation & Crystallization offers a scalable, efficient, and compliant method for hazardous liquid treatment, enabling industries to achieve zero liquid discharge, reduce environmental risks, and lower operational costs. With the expertise and advanced technology provided by ZheJiang VNOR Environmental Protection Technology Co., Ltd., industries can recover water for reuse at a high recovery rate, crystallize salts and toxic metals for safe disposal, significantly reduce hazardous waste disposal volumes, comply with stringent environmental regulations, and enhance operational sustainability.

If your facility is seeking to transform hazardous liquid treatment into a sustainable, compliant, and cost-effective process, contact ZheJiang VNOR Environmental Protection Technology Co., Ltd. to discover how Multi-effect Evaporation & Crystallization can optimize your hazardous liquid waste management strategy.