Views: 0 Author: Site Editor Publish Time: 2025-09-15 Origin: Site

A mvr evaporator uses mechanical vapor recompression to recycle energy within the evaporation process. This approach sets you apart from conventional systems that rely heavily on fresh steam and higher energy consumption. You will find these systems especially valuable in industries that require strict environmental compliance, such as industrial wastewater treatment, food processing, pharmaceuticals, and chemicals.

The global market for industrial evaporators is projected to reach USD 28.03 billion by 2030, with a CAGR of 5.1%.

MVR evaporator demand grows rapidly due to rising energy costs and stricter environmental regulations.

You can achieve up to 80% or more energy savings with advanced multi-stage designs, making your operations both cost-effective and sustainable.

You may notice that industries today demand more efficient and sustainable solutions for liquid concentration and purification. The mvr evaporator stands out as a modern answer to these needs. Unlike traditional evaporators, which rely on steam from external boilers, the mvr evaporator uses a mechanical compressor powered by electricity. This compressor increases the pressure and temperature of vapor produced during evaporation, allowing you to recycle it as a heat source. As a result, you can achieve significant energy savings and lower operational costs.

Tip: By choosing an mvr evaporator, you can reduce your energy consumption by up to 80% compared to conventional systems.

To help you understand the differences, see the table below:

| Feature | MVR Evaporators | Traditional Evaporators |

|---|---|---|

| Energy Source | Electricity (mechanical compressor) | Steam (external boiler) |

| Efficiency | 50-80% less energy consumption | Higher energy use |

| Operational Costs | Lower over time | Higher due to energy needs |

| Temperature Difference | 8°C to 15°C | Up to 180°C |

| Heat Transfer Area | Larger heat exchanger required | Smaller heat exchanger possible |

You will find mvr evaporators in many sectors. Food processing, chemicals, and wastewater treatment industries use these systems to cut energy expenses and support sustainability goals. Other common users include pharmaceuticals, metallurgy, and lithium battery manufacturing. These industries often require large-scale evaporation, making the mvr evaporator a practical and cost-effective choice.

You will find forced circulation evaporation-crystallization systems essential when you need to handle high-solid or corrosive fluids. These systems use powerful axial pumps to keep the liquid moving at high speeds. This design prevents scaling and allows for continuous operation, even with challenging materials like salt wastewater or caustic soda. You can achieve high crystal recovery rates and maintain stable performance for thousands of hours. Forced circulation systems work well in applications such as lithium recovery, metallurgy, and chemical manufacturing.

If you process heat-sensitive products or require gentle evaporation, falling film MVR evaporators offer a strong solution. These systems create a thin film of liquid that flows down the inside of vertical or horizontal tubes. The design supports low-temperature operation, which helps preserve product quality and flavor. You will also benefit from easy cleaning and maintenance, thanks to features like enlarged CIP nozzles and modular construction. The table below compares falling film evaporators to other MVR configurations:

| Feature/Benefit | Falling Film Evaporators | Other MVR Configurations |

|---|---|---|

| Energy Efficiency | High, with reuse of condensate and flash vapor | Varies |

| Maintenance | Easy, efficient cleaning | May require more effort |

| Flexibility | Custom-made for specific products | Less flexible |

| Hygiene | Fully welded, exchangeable components | Varies |

| Capacity Range | Modular, up to 80 tons/hour | Varies |

Hybrid and multi-effect MVR systems combine the strengths of different evaporation methods. You can use these systems to maximize energy efficiency and minimize operating costs. They reuse heat from one stage in the next, which reduces utility bills and supports zero liquid discharge goals. Automated controls make operation simple and stable. The following tables highlight the main advantages and considerations:

| Advantage | Description |

|---|---|

| Energy Efficiency | Up to 90% lower energy use than traditional units |

| Lower Operating Costs | Reduced steam and utility expenses |

| Gentle Processing | Low temperature difference preserves quality |

| Compact Design | Smaller footprint |

| Automated Control | Stable, easy operation |

| Aspect | Benefits | Limitations |

|---|---|---|

| Energy Efficiency | Reuses heat for more distillate | Higher initial investment |

| Scalability | Easy to expand production | Increased complexity with more stages |

| Waste Management | Reduces waste and supports zero discharge | Requires careful vacuum and pressure control |

| Environmental | Cuts emissions and water use | Not ideal for all product types |

You can select the right mvr evaporator configuration based on your process needs, product sensitivity, and sustainability goals.

You rely on several core components to ensure the performance and reliability of your mvr evaporator. The compressor stands at the heart of the system, driving the vapor recompression process. You also need a high-quality heat exchanger to transfer energy efficiently between vapor and liquid. The evaporation axial flow pump keeps fluids circulating at optimal speeds, which helps prevent scaling and maintains steady heat exchange.

| Component | Function |

|---|---|

| Compressor | The core of vapor recompression. |

| Heat Exchanger | Facilitates energy transfer between vapor and liquid. |

| Evaporation Axial Flow Pump | Drives high-volume fluid circulation and prevents scaling. |

Tip: Investing in advanced control systems can further enhance stability and automation in your operations.

You must select materials that withstand harsh industrial environments. Stainless steel, especially 316L grade, offers excellent corrosion resistance for pharmaceutical and food applications. Titanium alloys provide durability when you process seawater or strong acids. These choices directly affect the lifespan of your equipment, which can range from 5 to 15 years depending on usage and maintenance.

Stainless steel resists corrosion and supports hygiene.

Titanium alloys handle aggressive chemicals and high salinity.

Proper material selection extends equipment life and reduces downtime.

You will notice that raw material prices play a major role in the cost structure of mvr evaporator production. Metals such as copper, aluminum, and stainless steel make up a large portion of manufacturing expenses. Global commodity price changes, tariffs, and supply-demand shifts can quickly impact your unit costs.

| Raw Materials | Impact on Costs |

|---|---|

| Metals | Constitute a large portion of manufacturing expenses |

| Global prices | Directly affect evaporator unit costs due to supply-demand and geopolitical events |

When you compare manufacturing costs, mvr evaporators require a higher initial investment than conventional systems. However, you benefit from lower operating costs and improved energy efficiency over time.

| Type of Evaporator | Initial Investment Cost | Operating Costs | Energy Efficiency |

|---|---|---|---|

| MVR Evaporators | High | Lower | Improved |

| Conventional | Lower | Higher | Standard |

You can rely on MVR evaporators to achieve zero liquid discharge in industrial wastewater treatment. These systems work after membrane concentration, handling high-concentration wastewater with remarkable efficiency. By compressing steam, they recover heat energy and reduce energy consumption. This process not only lowers operational costs but also supports environmental compliance. You will find that evaporation technology is less labor-intensive than other methods and can treat a wider range of waste streams. It also concentrates waste more effectively, which leads to lower disposal costs.

| Evidence Description | Key Points |

|---|---|

| MVR's Position in ZLD | MVR is used after membrane concentration to treat high-concentration wastewater. |

| Efficiency | MVR achieves thorough reduction through efficient evaporation and thermal energy reuse. |

Note: MVR evaporators are especially valuable in industries like lithium battery manufacturing, where high-concentration organic wastewater is common.

You will see strong benefits when you use MVR evaporators in pharmaceutical manufacturing. These systems provide precise heating, which helps you improve drug purity and consistency. They concentrate active ingredients while protecting their stability and biofunctions. You can save over 80% in energy consumption compared to single-effect evaporators and reduce cooling water needs by up to 90%. MVR systems are reliable and easy to control, making them ideal for applications where product integrity is crucial.

Achieve significant energy savings.

Maintain the stability and quality of pharmaceutical products.

Reduce operational costs and water usage.

You can use MVR evaporators to concentrate liquids such as milk, juice, and sweeteners while preserving flavor and nutritional value. Many food processors have reported reduced operational costs and lower carbon emissions. For example, a New Zealand plant used three MVR units for continuous milk powder production, achieving significant emission reductions. In dairy operations, MVR technology has shortened the return on investment period from three years to just 14 months. You will also benefit from up to 98% steam savings and unmatched energy efficiency.

Preserve product quality and taste.

Lower energy and gas costs.

Enhance sustainability in food processing.

You will find that the chemical and new energy materials sectors represent the largest market for MVR evaporators, holding about 40% of the market share. These systems enhance energy efficiency, improve product quality, and support zero liquid discharge. In the new energy sector, you can use MVR evaporators to concentrate lithium solutions and recover valuable metals for battery production.

| Sector | Role of MVR Evaporators | Applications |

|---|---|---|

| Chemical Industry | Enhances energy efficiency, improves product quality, facilitates ZLD | Concentration of chemical solutions, solvent recovery, wastewater treatment |

| New Energy Materials | Concentrates lithium solutions, recovers metals, ensures high purity | Lithium, cobalt, and nickel recovery for battery production |

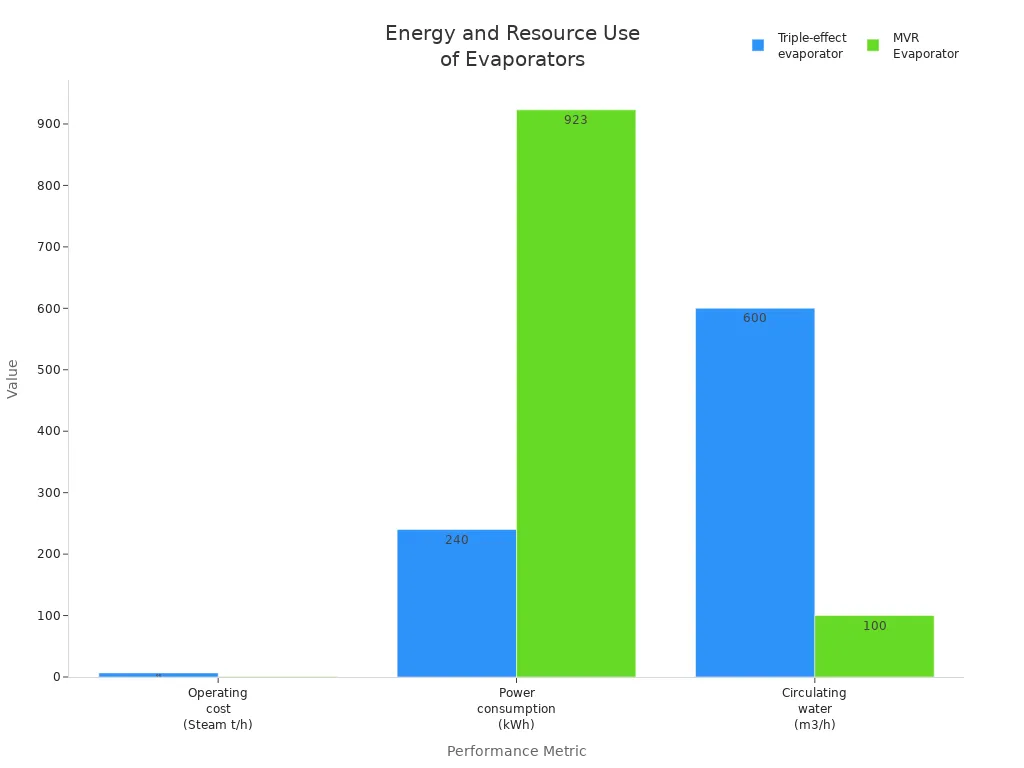

You operate in a market where energy efficiency drives both cost savings and environmental responsibility. When you compare leading evaporation technologies, you see clear differences in resource consumption. The table below highlights how triple-effect evaporators and MVR systems perform in key areas:

| Item | Triple-effect evaporator | MVR Evaporator |

|---|---|---|

| Operating cost (Steam t/h) | 6.6 | 0.9 |

| Power consumption (kWh) | ~240 | ~923 |

| Circulating water (m³/h) | 600 | 100 |

You notice that MVR systems require much less steam and circulating water. This reduction leads to lower utility bills and a smaller environmental footprint. Although power consumption is higher, the overall operating cost drops because electricity prices remain more stable than steam generation costs. The following chart visually compares these metrics:

Tip: By choosing advanced evaporation technology, you can achieve up to 80% energy savings and reduce water usage by over 80%.

You see rapid changes in the industry as companies race to deliver better performance and value. Leading competitors focus on several key areas:

Rising investments and funding drive research and development for new solutions.

Mergers and acquisitions help companies expand their product portfolios and enter new markets.

Customization and personalization allow you to select systems tailored to your specific process needs.

Digital transformation brings cloud-based monitoring, AI-powered analytics, and automation, which improve operational efficiency and predictive maintenance.

You benefit from these innovations by gaining access to more reliable, flexible, and efficient evaporation systems. Staying informed about these trends helps you make smarter investment decisions and maintain a competitive edge.

You may encounter significant challenges when processing liquids with high boiling point elevation. This property restricts operational flexibility because these fluids require more heat input to reach evaporation. As a result, you might see reduced energy efficiency and increased operational costs. When you work with solutions containing salts or other dissolved solids, the system must deliver higher temperatures, which can impact both performance and equipment longevity. Selecting the right process design becomes essential to maintain efficiency and reliability in these demanding applications.

Scaling and fouling can disrupt your operations and reduce heat transfer efficiency. You need to address these issues to keep your system running smoothly. Self-cleaning heat exchangers offer a practical solution by managing deposits from biological, crystallization, chemical, or particulate sources. Some advanced systems use a fluidized bed of solid particles inside the heat exchanger tubes. This approach allows for continuous cleaning and helps minimize fouling, so you can maintain stable performance and reduce downtime. Regular monitoring and proactive maintenance further support long-term reliability.

Tip: Implementing self-cleaning technologies can extend equipment life and lower maintenance costs.

Maintaining stable operation under varying load conditions requires careful attention to several factors. You must monitor feed rate, compressor performance, separator design, and pump efficiency. Each element plays a role in ensuring consistent evaporation and product quality.

| Factor | Impact on Stability |

|---|---|

| Feed Rate | Influences heat transfer; too high reduces evaporation, too low increases temperature. |

| Steam Compressor Performance | Controls system efficiency; flow rate and temperature must stay within optimal ranges. |

| Gas-Liquid Separator Design | Ensures effective vapor-liquid separation; must match temperature and viscosity of materials. |

| Forced Circulation Pump | Supports liquid movement; poor performance can cause inefficiency or stagnation. |

You operate in an industry marked by intense competition, rapidly evolving technology, and the constant need to adapt to changing market demands. Addressing these technical challenges helps you stay ahead and deliver reliable, efficient solutions.

You will see rapid changes in the industry over the next five years. Market analysts expect strong growth, driven by several important factors:

Demand for energy-efficient technologies continues to rise.

Advancements in system design and smart controls improve operational performance.

Applications expand in chemical processing, wastewater treatment, and food & beverage sectors.

Sustainability and eco-friendly solutions remain a top priority for manufacturers and end users.

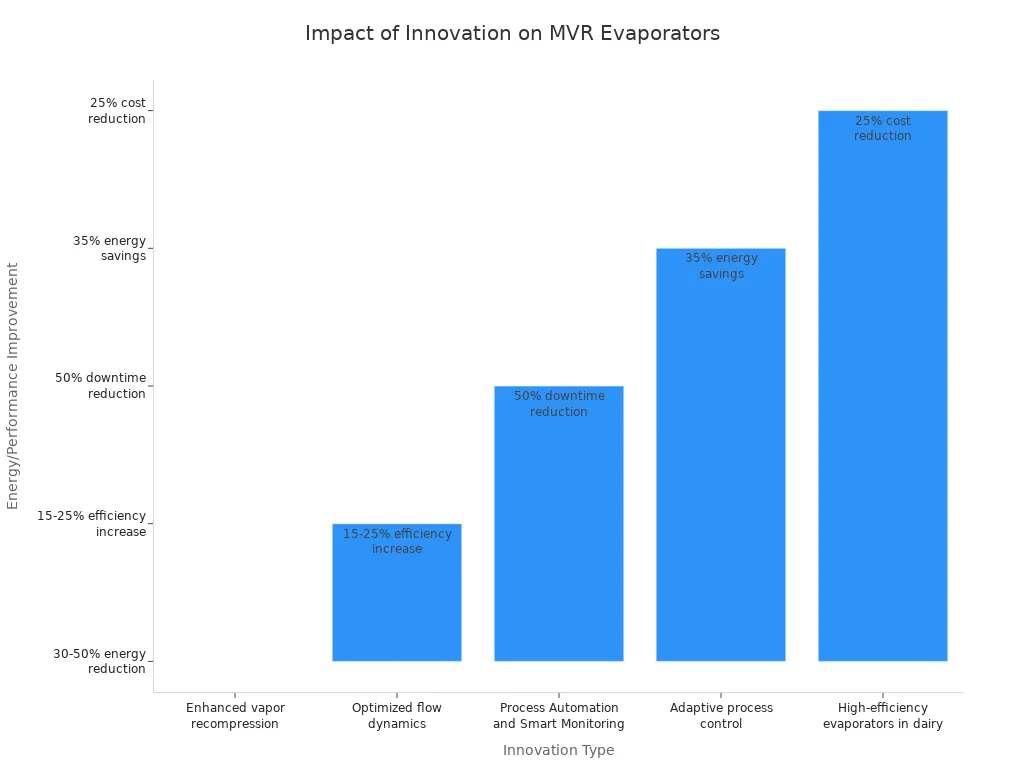

You can expect continuous innovation to shape both upstream supply and downstream applications. Manufacturers invest in enhanced vapor recompression systems, which recover more latent heat and reduce energy consumption by up to 50% compared to older models. Optimized flow dynamics, achieved through advanced modeling, deliver up to 25% higher efficiency. High-performance materials extend equipment life, especially in corrosive environments. Automation and smart monitoring reduce downtime by half, while adaptive process control helps you save energy during load changes.

| Innovation Type | Impact Description | Energy Savings/Performance Improvement |

|---|---|---|

| Enhanced vapor recompression systems | Recover latent heat, reducing energy consumption by 30-50%. | 30-50% energy reduction |

| Optimized flow dynamics | Achieve 15-25% higher efficiency through advanced modeling. | 15-25% efficiency increase |

| High-Performance Materials | Extend equipment life by over 10 years in harsh conditions. | Longevity improvement |

| Process Automation and Smart Monitoring | Reduce downtime by up to 50% with AI-driven controls. | 50% downtime reduction |

| Adaptive process control | Adjust to load changes, saving up to 35% energy. | 35% energy savings |

You will notice emerging economies investing in industrial infrastructure to boost energy efficiency. The integration of smart technologies in evaporation systems will help you achieve better results and meet stricter environmental standards. Expanding applications in desalination and chemical processing present new opportunities for growth. Ongoing research and development will position the industry for widespread adoption and robust expansion.

Tip: Staying informed about new technologies and market trends will help you make better decisions and stay ahead in a competitive landscape.

You have explored the entire industry chain of advanced evaporation technology, from the critical upstream supply to the diverse downstream applications. Each link in this chain plays a vital role in shaping the performance, reliability, and value you receive from your investment. When you select high-quality components and materials, you set the foundation for long-lasting and efficient systems. Reliable suppliers and robust manufacturing practices help you minimize risks and ensure consistent operation.

Downstream, you see how these systems transform industries. You can achieve zero liquid discharge in wastewater treatment, improve product quality in pharmaceuticals, and enhance efficiency in food and chemical processing. These applications not only support your operational goals but also help you meet strict environmental standards and reduce costs.

Remember: The synergy between upstream supply and downstream demand drives innovation and growth across the industry.

If you want to stay ahead, you should pay close attention to both segments. Smart investment decisions depend on understanding how supply chain optimization and application trends interact. As new technologies emerge, you will find even greater opportunities to boost efficiency and sustainability.

VNOR continues to lead by example, offering solutions that combine energy savings, reliability, and adaptability. By choosing advanced systems, you position your business for long-term success in a rapidly evolving market.

Focus on quality at every stage.

Monitor trends in both supply and application.

Embrace innovation to maximize your competitive advantage.

You hold the key to shaping the future of your operations and the broader industry.

You drive success in the MVR evaporator industry by connecting upstream supply with downstream applications.

Optimizing your supply chain gives you better access to materials and technology, which boosts efficiency and sustainability.

Integrating both segments helps you manage costs, meet regulations, and scale your operations.

Companies like VNOR lead the way by recovering valuable resources in chemicals, ensuring purity in pharmaceuticals, and delivering energy savings in food, mining, and textiles.

Ongoing innovation and supply chain strategies will shape your future growth.

You gain significant energy savings—often over 80%—compared to traditional evaporators. MVR systems recycle vapor as a heat source, which lowers your operational costs and supports sustainability goals.

You see the greatest benefits in wastewater treatment, food and beverage processing, pharmaceuticals, and chemical manufacturing. These sectors require efficient liquid concentration and strict environmental compliance.

You should schedule regular inspections, clean heat exchangers, and monitor compressor operation. Automated control systems help you detect issues early and keep your system running efficiently.

Yes, you can. MVR evaporators operate at low temperatures, which helps you preserve the quality of heat-sensitive materials like vitamins, proteins, and active pharmaceutical ingredients.

Material selection, maintenance frequency, and process conditions all impact lifespan. Using corrosion-resistant alloys and following a strict maintenance schedule can help your equipment last 10 years or more.

Tip: Always consult your equipment supplier for specific maintenance guidelines and recommended materials.