Views: 0 Author: Site Editor Publish Time: 2025-08-25 Origin: Site

Evaporator Type | Steam Needed (kg) for 1 kg Water Gone |

|---|---|

Single Effect | |

Double Effect (M.E.E.) | 0.6 |

Triple Effect (M.E.E.) | 0.4 |

This method makes running costs lower and helps improve the process. Engineers and technicians like these savings. They help make work better for the planet and help companies earn more money.

Multi-effect evaporators help save energy. They reuse steam in many steps. This lowers fuel costs and helps the environment.

These machines heat liquids in different stages. Vapor from one step heats the next step. This makes the process work well.

Picking the right flow arrangement is important. You can use forward, backward, or parallel flow. This helps with different liquids and makes the machine work better.

Good design means choosing the right number of effects. You also pick the heat transfer area and materials. This matches the product and job needs.

Main parts include heat exchangers and vapor separators. Condensers, pumps, and instruments help the machine run safely and smoothly.

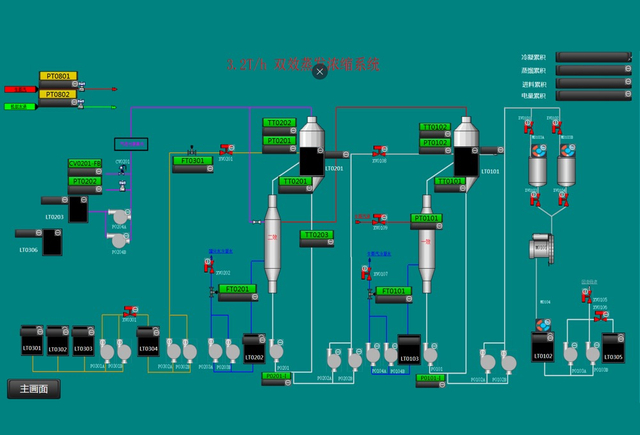

Automation and controls keep temperatures steady. They also keep feed rates steady. This makes the product better and saves energy.

Regular care, cleaning, and checks are needed. This stops scale and corrosion. It helps the machine last longer and lowers costs.

Multi-effect evaporators are used in many industries. They help in food, sugar, paper, and wastewater treatment. They save energy and help meet quality rules.

A multi-effect evaporator is a special machine. It uses heat to take water or other liquids out of mixtures. Single-effect evaporators use steam one time. Multi-effect evaporators use steam again and again in different steps. Each step works at a lower pressure and temperature than the last one. The vapor from one step heats the next step. This saves a lot of energy.

Multi-effect evaporators need less steam. They help companies spend less money on fuel. Engineers pick these machines because they can make liquids very strong. The design uses materials that do not rust. It can be built in parts and can work with computers. These things help companies save money and protect nature.

The system works in a simple order:

First, it warms up the mixture to help it move and heat better.

The warm mixture goes into the first step. Steam heats it and some liquid turns into vapor.

The vapor from the first step goes to the second step. It heats and turns more liquid into vapor at lower pressure.

This happens again in each step. Each step uses vapor from the last step for heat.

At the end, the last vapor cools down and turns back into liquid. The system saves this liquid to use again.

The thick liquid leaves the machine for more work.

Workers clean and check the machine often to keep it working well.

This way, the machine uses energy wisely. It uses heat again and does not waste steam. The system can work with different mixtures. Forward feed is good for mixtures that need gentle heat. Backward feed is good for thick mixtures. Some new designs use vacuum and special membranes to save even more heat.

Multi-effect evaporators are important in many jobs. They help companies use less energy and save money. They also help meet high quality rules. Food and drink companies use them most. They help make juice and milk thicker. Medicine companies use them to make pure ingredients. Other jobs like cosmetics, farming, chemicals, and paper also use these machines.

Note: Studies show these machines can save up to half the energy in big factories. Companies often get their money back in one to three years after buying them.

Here is a table that shows which jobs use these machines most:

Industrial Sector | Market Share / Key Insight |

|---|---|

Food and Beverage | Biggest share at 35%; needed for making and saving products |

Pharmaceutical | Big share; fastest growth because of medicine making and cleaning |

Cosmetics | Small share; steady growth because of careful mixing |

Agriculture | Small share; growing because of making plant extracts and fertilizers |

Petrochemical | Small share; used for making chemicals and helping the environment |

Pulp and Paper | Used for saving water and stopping liquid waste |

Wastewater Treatment | New area for these machines |

Desalination | New area for these machines |

Multi-effect evaporators are flexible and can handle a lot of work. They help save steam and cooling water. This makes them a smart choice for today’s factories.

Multi-effect evaporators use a step-by-step process to make solutions stronger. Each step uses vapor from the last step as heat. This lets the system work at lower pressure and temperature each time. When pressure goes down, the liquid boils at a lower temperature. This helps vapor from one step heat the next step. The system uses the same heat again, so it saves energy.

The evaporation process in these machines has these main steps: 1. The system warms the feed with liquid from the last step. 2. The first step gets steam, which heats the liquid and makes it boil. 3. Vapor from the first step goes to the second step and heats it. 4. Each step works at lower pressure, so heat moves well and more liquid boils. 5. The last step cools the vapor, and the system collects the thick product.

This way, multi-effect evaporators save energy and lower costs. Engineers build these machines to get the most evaporation and use less steam.

Heat transfer is very important for these machines to work well. The design must help heat move from steam to liquid in every step. Many things affect how well heat moves, like the number of steps, the area for heat, the temperature difference, and the heat transfer rate.

Design Aspect | Effect on Heat Transfer Efficiency | Notes |

|---|---|---|

Number of stages | More steps cost more money; best number saves money and energy | |

Heat transfer area (A) | Same area keeps heat moving at the same rate | Same area means changing temperatures in each step |

Temperature difference (ΔT) | ΔTn = Tn-1 - Tn is picked for even heat movement | Makes sure each step has the same heat transfer, which helps the whole system |

Overall heat transfer coefficient (U) | Kept the same to make design easy | Makes it easier to figure out heat transfer |

Practical design approach | All steps and heat parts are the same size | Makes building and running the machine easier, but needs careful temperature choices |

Example case | Four steps use only 25% of the steam compared to one step | Four steps are often the best choice for saving money |

Engineers also look at how the refrigerant moves inside the machine. If the flow is not even, heat transfer can drop by up to 40%. Good design makes sure the refrigerant spreads out evenly. This helps the system work better and stops problems like liquid getting into the compressor. New designs, like the rectifier nozzle-type, help keep heat transfer steady and the machine running well.

Steam economy shows how well the machine uses steam to take out water. Multi-effect evaporators do better by using vapor as heat in each step. More steps mean better steam economy.

Steam economy gets better with more steps in the machine.

A three-step system usually gets a steam economy of about 3. This means 1 kg of steam boils away 3 kg of water.

In milk factories, some systems reach steam economies as high as 5.5.

Most jobs, like food, medicine, chemicals, paper, and water cleaning, use these machines to save energy.

Normal steam economy numbers go from 3 for three-step systems up to 5.5 or more for new designs.

Multi-effect evaporators help companies use less energy and spend less money by making steam economy better. Engineers pick the number of steps and design the machine to get the best mix of savings and cost.

Multi-effect evaporators can move liquid and vapor in different ways. The way they move affects how well the system works. It also changes how much energy is saved. Some ways are easier for handling different products. Engineers pick the best way for each job. They look at the type of feed and what the product is like. They also think about how much evaporation is needed.

Forward feed means the liquid starts in the first effect. It goes from one effect to the next until the last one. Each effect has lower pressure and temperature than the one before. The pressure difference pushes the liquid forward. This means pumps are not needed. This way is good for liquids that make scale. The thickest product leaves at the lowest temperature. Forward feed helps protect products that are sensitive to heat.

Tip: Forward feed works well in medicine factories. It is also used in paper mills and sugar factories. It is best when the feed is hot or the product does not like heat.

Forward feed is not good for cold feeds. Later effects have lower temperatures. This can make less vapor and lower evaporation. The setup can be tricky in some jobs, like making fresh water from salt water.

Backward feed moves liquid from the last effect to the first. It goes from low pressure to high pressure. Pumps are needed to move the liquid backward. This way is best for cold feeds. The fresh liquid gets heated at the highest temperature. This helps more liquid turn into vapor. It is also good for thick or sticky products. The thickest liquid stays at the highest temperature. This makes it easier to flow.

Backward feed is used in milk and yogurt factories. The high temperature in the first effect helps make thick liquids thinner. This helps them evaporate faster. The main problem is that pumps are needed between effects. This makes the system cost more and harder to build.

Parallel feed splits the feed into parts. Each part goes into a different effect at the same time. Each effect gets its own share of the feed. This way lets workers change how the system works. It can handle feeds that are not the same. Parallel feed is not used often. It helps when the process needs to change quickly. It is also good for special products.

Flow Arrangement | Advantages | Disadvantages | Applications |

|---|---|---|---|

Forward Feed | No pumps needed; good for scale-making liquids; product leaves at lowest temperature | Not good for cold feeds; tricky for making fresh water | Medicine, Paper, Sugar |

Backward Feed | Good for cold feeds; works well with thick liquids | Needs pumps between effects | Milk, Yogurt |

Parallel Feed | Can change how it works; handles different feeds | Not used much; may need special controls | Special jobs |

Note: Picking the right way to move liquid and vapor can help save energy. It can make the system work better and easier to use.

Engineers pick different flow setups for multi-effect evaporators. The way liquid and vapor move changes how much energy is used. It also affects how good the product is and how hard the system is to run. Each setup has its own good points for certain jobs.

Flow Configuration | Flow Direction Between Condensate and Feed/Concentrate | Operational Characteristics | Energy/Operational Benefits |

|---|---|---|---|

Forward Feed | Condensate and feed-concentrate move in the same direction | Vacuum pressure can pull feed through system | Simplifies feed movement, no pumps needed |

Backward Feed | Concentrate flows opposite to condensate | Pumps required between stages | Lower heating costs due to flow arrangement |

Parallel Feed | Feed is supplied separately to each stage | Simplest design | Allows independent stage feeding, flexible operation |

Forward feed means the feed and concentrate move together. They go from the first effect to the last effect. The vacuum helps pull the feed through each stage. This setup does not need pumps between effects. People use forward feed when the feed is hot. It is also good when the product does not like heat. This setup makes the system simple. It also needs less fixing.

Backward feed moves the concentrate the other way from the condensate. The feed goes into the last effect first. It then moves toward the first effect. Pumps push the liquid between stages. This way works well for cold feeds and thick products. The hottest steam heats the thickest liquid. This helps save on heating costs. People use backward feed when the product gets thicker as it boils.

Mixed feed uses both forward and backward flow. Some stages use forward feed. Other stages use backward feed. This helps balance energy use and product quality. Mixed feed can handle feeds that change or need special care. People pick mixed feed when the other ways do not work for everything.

Multi-effect evaporators come in different shapes and builds. Each type works best for certain products and jobs. The design changes how heat moves, how much energy is used, and how easy it is to fix.

Engineers often put several evaporators in a row to save energy.

Most systems use vertical tube evaporators. Vapor from one effect heats the next.

Each effect has a shell and tube heat exchanger called a calandria. It moves heat from steam or vapor to the solution.

The last effect connects to a vacuum pump. This helps reuse heat and lowers boiling points.

This setup uses less steam and can evaporate more liquid.

Steam economy gets better with more effects. It can reach about 0.8 times the number of effects.

Multi-effect evaporators need more space and more pumps because of extra pipes.

Using vapor heat again lowers boiling points in later effects. This saves energy.

Horizontal tube evaporators have tubes lying flat inside the shell. Steam heats the liquid inside the tubes. This type is good for liquids that are thin and do not clog. People use horizontal tube designs where cleaning is easy and space is tight.

Vertical tube evaporators have tubes standing up. Liquid moves inside the tubes. Steam heats from the outside. This design helps natural mixing. Vertical tube types can handle more liquid and work for strong mixing. Many factories use vertical tube evaporators for big jobs.

Falling film evaporators let liquid make a thin layer as it goes down inside vertical tubes. Steam heats the outside of the tubes. This design gives short heating time and gentle heat. Falling film types are best for products that do not like heat, like fruit juice and milk. The thin layer stops clogging and helps heat move better.

Rising film evaporators use vapor inside the tubes to push liquid up. The liquid makes a film as it rises. This type is good for thin liquids and some clogging. Rising film designs move heat well and work for medium-sized jobs.

Forced circulation evaporators use pumps to move liquid fast through the tubes. This strong flow stops solids from settling and lowers clogging. People pick forced circulation for liquids with lots of solids or when crystals might form. This type works for tough jobs and materials that do not mind heat.

Picking the right multi-effect evaporator depends on many things. Engineers match the evaporator to the product and job needs.

What the product is like matters most. If it is sensitive to heat, clogs easily, foams, has solids, or is thick, it changes the choice.

Other things to think about are how much distillate and concentrate there is, vapor speed, heat transfer, and what it is made of.

The evaporator should move heat well with a small area to save money.

Good designs keep vapor and liquid concentrate apart.

Materials must not rust or clog to make fixing easier.

Job needs like size, steam use, heating area, and what the feed and concentrate are like help pick the type.

Special ways, like downstream or reverse, and types like forced circulation, fit certain products.

Products that do not like heat need low temperature and short heating time. This means low pressure and small product size.

Thick or solid products move heat slower, so forced circulation or vertical tube types may be better.

The right design makes the evaporator work well, saves steam, and fits the job.

Tip: Always think about how the product handles heat and clogging before picking a multi-effect evaporator. The best choice saves energy, cuts downtime, and keeps the product good.

Heat exchangers are very important in a multi-effect evaporator. They move heat from steam or vapor to the liquid. This helps make the liquid thicker. Engineers design them to move heat well and not waste energy. There are some main things to check for heat exchangers:

Capacity means how much liquid turns into vapor each hour.

Economy shows how much vapor comes from each unit of steam. This tells us how well energy is used.

Steam use is found by dividing capacity by economy.

The heat transfer rate depends on the area, the heat transfer number, and the temperature difference. This rate shows how well the evaporator works.

Workers must watch some things to keep the heat exchanger working well. If steam is too hot, it can lower how well heat moves. The steam pressure helps the liquid boil. More pressure, if safe, makes more liquid boil. A strong vacuum in the last step helps the liquid boil at a lower temperature. This makes evaporation easier. Keeping the liquid level steady in each step stops scale and keeps boiling even. Watching temperature and pressure changes helps find blockages or scale early.

A good heat exchanger helps the evaporator work well and last long.

Vapor separators help the evaporator work better. They split vapor from liquid after each step. By draining and filling liquid, they help move vapor and liquid the right way. This lets the best heat transfer happen sooner and more often. It makes the heat transfer number higher.

Vapor separators also lower the pressure drop by about 15%. Less pressure drop means better heat transfer and less energy used. How well the separator works depends on how much liquid it drains compared to what comes in. Vapor separators send drained liquid back to places with lots of vapor. This keeps the machine steady and stops it from getting too hot.

Some systems use vapor separators to make the machine work over 7% better. They also help the machine heat up more and change when needed. With good controls, vapor separators keep the machine working well, even if things change.

Tip: Check vapor separators often to stop scale and keep the machine running well.

Condensers take vapor from the last step of the evaporator. They cool the vapor and turn it back into water. This is important because it keeps the vacuum strong in the last step. It also lets the system use water again or save heat.

There are two main kinds of condensers:

Surface condensers: Vapor goes over tubes with cold water inside. The vapor turns to water but does not mix with the cooling water.

Direct contact condensers: Vapor mixes with cold water. The water takes the heat and makes the vapor turn to water.

Engineers pick the condenser type by looking at water quality, space, and cost. A good condenser quickly takes away vapor and keeps pressure low. Workers must look for leaks and scale, which can make it work less well.

A good condenser helps the evaporator save energy and keeps the process safe.

Pumps and piping are very important in a multi-effect evaporator. Pumps move liquid from one effect to another. They help keep the flow steady and the process smooth. Engineers pick pumps based on the liquid type and how thick it is. They also look at how fast the liquid needs to move. Centrifugal pumps are good for thin liquids. Positive displacement pumps work for thick or sticky mixtures.

Piping links all the parts of the evaporator together. It carries liquid, vapor, and steam between each effect. Stainless steel pipes do not rust and last a long time. The size of the pipe is important. Big pipes help thick liquids move better. Small pipes are fine for thin liquids and vapor. Engineers plan piping to have few bends. Fewer bends help the liquid flow easily and save energy.

Valves help control how liquid and vapor move. Workers use control valves to change flow rates. Safety valves stop pressure from getting too high. Check valves keep liquid from going backward. Good piping stops leaks and makes cleaning simple. Pipes with insulation keep heat inside and save energy.

A good pump and piping setup helps the evaporator work well. It lowers downtime and keeps things safe. Regular checks and fixing stop clogs and leaks. Engineers teach workers to find problems early. Pumps and pipes must fit the evaporator and the product.

Instrumentation helps keep the evaporator safe and working well. Engineers use tools to watch and control the system. These tools check water and steam chemistry. They help find problems before they get worse.

Some main instruments are:

pH meters: These check how acidic the water is. If pH goes below 8.0, workers must stop the system to stop rust.

Conductivity meters: These check for salts in the water. Conductivity after cation exchange shows if water is pure.

Sodium analyzers: These find sodium in the water. Too much sodium can cause scale and make the evaporator work less well.

Silica analyzers: These check for silica. Too much silica can make deposits and block heat.

Chloride analyzers: These find chloride ions. Chlorides can cause rust and hurt metal parts.

Dissolved oxygen meters: These show how much oxygen is in the water. Oxygen can make rust form faster inside the evaporator.

Sampling systems take water, steam, and condensate for testing. Engineers use these samples to look for dirt and rust. Watching these things helps protect the evaporator from harm. It also keeps the product good.

Makeup water tools check pressure, temperature, flow, and conductivity. These tools make sure only clean water goes into the evaporator. Watching the condensate pump discharge helps find problems fast. Engineers use these tools to keep the right water chemistry and stop turbine damage.

A strong instrumentation system helps the evaporator work well. It lets workers act fast when things change. Checking and fixing tools often keeps them working right. Good instrumentation keeps equipment safe and helps the process run better.

Engineers always look at the feed first when designing a multi-effect evaporator. The feed’s features decide how the whole system will work. Many things matter:

Viscosity: Thick feeds move slowly and can block tubes. High viscosity makes heat move slower and slows down evaporation. Engineers might pick forced circulation or bigger tubes for thick feeds.

Concentration: Feeds near saturation can make solids settle or block pipes. Workers must watch concentration to stop clogs and pump issues.

Temperature: Hot feeds help evaporation and save energy. Preheating with hot condensate makes the system work better and reach steady running faster.

Feed Rate: The amount of feed going in changes the final product. Careful control keeps things steady and stops overloading.

Solids Content: Too many solids can hurt pumps and cause blocks. Workers must keep solids low to help the system run well.

In some systems, like those with parallel feeds, engineers use separate controllers for each effect. Tight control of solids is not always needed, but too many solids can cause trouble. Vacuum and steam pressure also change how the feed acts, but these are more about the whole system.

Tip: Always match the evaporator design to the feed’s features. This helps get high evaporation and keeps the system working well for a long time.

Picking the right number of effects is very important in evaporator design. Each effect uses vapor from the last step to heat the next one. This saves steam and makes the system work better. But adding more effects costs more money and makes things more complex.

Engineers try to save steam but also watch costs. More effects save more steam, but they cost more to build. The best number of effects is found by looking for the lowest total cost, which means both steam and equipment costs. Most systems use three to five effects for good savings and fair cost.

Many things affect this choice:

The boiling point of the feed and if it is sensitive to heat

How thick the feed is and how it changes as it boils

How much product is needed every hour

The temperature of the steam and the cooling water

The vacuum level and the temperature drop between steps

The plant’s height above sea level, which changes boiling points

Engineers also think about how easy the system is to use and fix. They want a design that gives strong evaporation, simple controls, and few problems.

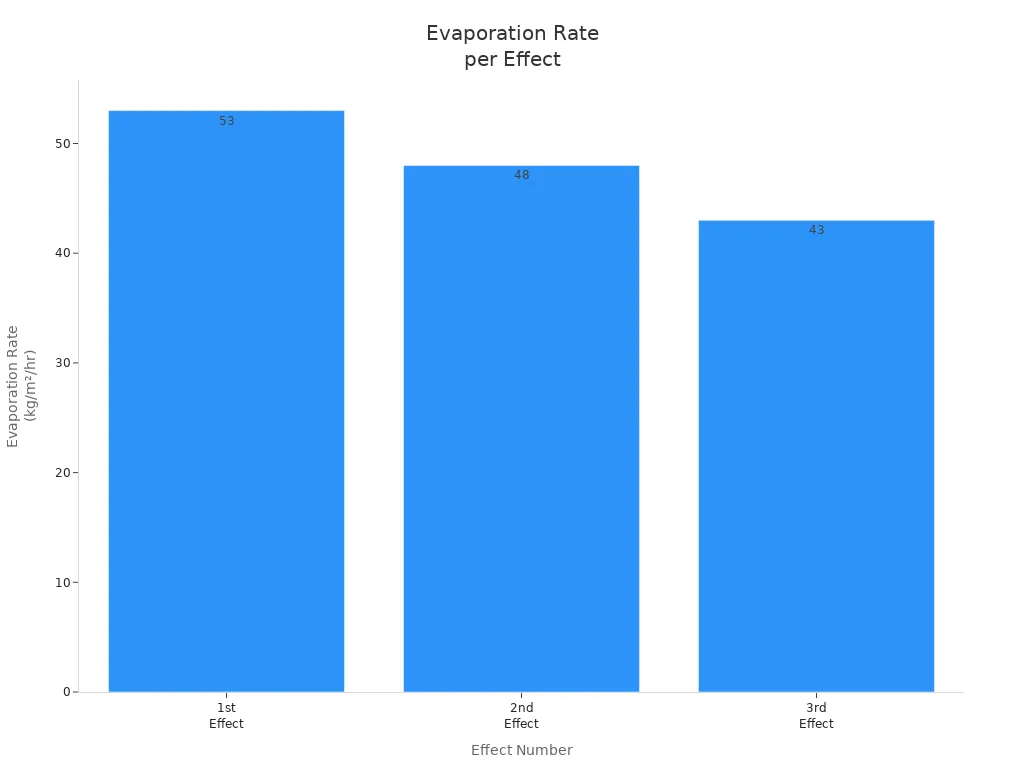

The heat transfer area is a key part of evaporator design. It tells how much liquid can be boiled away in each step. Engineers find the needed area by dividing the amount to evaporate (in kg/hr) by the evaporation rate per area (in kg/m²/hr) for each step.

The evaporation rate is different in each step. For example, in a triple-effect evaporator, the usual rates are:

Effect Number | Evaporation Rate (kg/m²/hr) |

|---|---|

1st Effect | 53 |

2nd Effect | 48 |

3rd Effect | 43 |

This table helps engineers pick the right heating surface for each step. Once they know the area, they can design the tube bundle and other parts. The right heat transfer area helps the system reach its goal and work well.

A good heat transfer area keeps evaporation steady and stops slowdowns. It also helps keep the product good and saves energy.

Steam economy tells us how well the machine uses steam. It compares water boiled away to steam used. Engineers check this number to see if energy is saved. A bigger steam economy means less energy is wasted.

To find steam economy, engineers do these things: First, they see how much water is boiled off. Next, they measure how much steam is used for heat. Then, they divide the water boiled by the steam used.

Single-effect evaporators have a steam economy from 0.75 to 0.95. This means less than one kilogram of water boils for each kilogram of steam. Multi-effect evaporators do better. They use vapor from one step to heat the next step. This works because each step has lower pressure and temperature. Vapor from one stage heats the next, so less new steam is needed.

Engineers also use math to track all flows in the system. They look at feed, product, vapor, steam, and water that comes out. They check the heat in each part to guess how much water boils and how much steam is used. Some machines use TVR to squeeze vapor and use it again for heat. This makes steam economy even higher.

A good design uses these ideas to save more energy and get high steam economy.

Tip: Always check steam economy when planning the machine. This helps make sure it saves energy.

Vapor bleeding helps the machine work better. Engineers take vapor from the middle steps. They use it to warm up the feed or help other jobs. This way, the system needs less new steam. It uses vapor that would be wasted.

When vapor bleeding is used with other energy-saving tricks, like TVR or linking with other systems, even less steam is needed. Studies show taking vapor from effects saves a lot of energy. This makes the whole machine use less energy.

Vapor bleeding is a smart way to use all the heat in the system. It helps companies spend less money and save energy.

Note: Vapor bleeding works best if planned early. It can save a lot of steam.

Picking the right materials for the machine is very important. The parts must last long and not rust. Engineers look at what goes in, the heat, and the chemicals before picking.

Aspect | Details / Best Practices |

|---|---|

Material Selection | Use stainless steel or special alloys that do not rust. |

Corrosion Influencing Factors | Acidic pH makes rust worse; high heat makes rust faster; chlorides and fluorides make small holes, especially near welds. |

Corrosion Types | Uniform corrosion means metal wears away everywhere, often from acids; Pitting corrosion means small holes, made worse by chlorides or fluorides. |

Protective Measures | Do not let pH get too acidic; keep chloride low; use special protection like sacrificial metals; put on coatings like Teflon, polyester, or ebonite. |

Additional Practices | Clean feed water to stop crusts; use chemicals to stop crusts; clean with chemicals or tools when needed. |

Engineers stop rust by keeping pH safe and lowering chloride. They may use coatings or special metals to protect parts. Cleaning the feed water and using chemicals helps the machine last longer. Cleaning the machine often keeps it working well.

Good material choices help the machine stay safe and last longer. Smart design keeps the equipment safe and saves money on repairs.

Vacuum operation is very important for how well multi-effect evaporators work. Lowering the pressure inside each effect makes the liquid boil at a lower temperature. In many systems, the boiling point drops to about 35–40°C. This is much lower than normal boiling at regular air pressure. The bigger difference between the steam and liquid temperatures helps the liquid turn into vapor faster.

There are many good things about using a vacuum:

Lower Energy Use: The system needs less heat to boil the liquid. This saves energy and lowers costs.

Better Heat Reuse: Vapor from one effect can heat the next effect. The lower boiling point makes this work even better.

Gentle Treatment: Some products, like milk or juice, need gentle heat. Vacuum operation keeps these products safe from harm.

Flexible Energy Sources: The system can use extra heat from other plant jobs, not just high-quality steam.

Mechanical vapor recompression (MVR) systems make vacuum operation even better. These systems squeeze the vapor made during evaporation. The squeezed vapor gets hotter and can heat the feed liquid right away. This way, the system needs less extra steam or cooling. MVR systems often use only 50–60 kWh of energy for each cubic meter of distillate. This shows they save a lot of energy.

Vacuum operation also lets engineers lower the pressure in each step. This setup lets vapor from one stage heat the next stage. The boiling temperature in the last effect can be around 70°C or even lower. This means the system needs less outside heating and cooling. The whole process works better and saves more energy.

Note: Vacuum evaporators, especially with heat recovery, can cut energy use by about 30%. This makes them a great choice for big jobs in food, chemical, and wastewater plants.

Mathematical modeling helps engineers design and control multi-effect evaporators. These models show how the system will act in different situations. They also help move designs from the lab to the factory.

There are different kinds of models:

Steady-State Models: These models use the laws of thermodynamics. They think the system runs without changes over time. Engineers use them to figure out heat and mass balances, guess steam use, and check how well the system works.

Dynamic Models: These models watch changes over time. They use material and energy balances to show what happens during start-up, shutdown, or when the feed rate changes.

Distributed Parameter Models: These models look at changes along the evaporator. They help engineers see how temperature and concentration change from one end to the other.

Empirical and Semi-Empirical Models: These models use real plant data and some theory. They help match the model to what really happens, especially for tricky systems like falling film evaporators.

State-Space Models: These models help with advanced control. They let engineers guess system states and design controllers that handle many things at once.

Most models think the liquid and vapor have the same properties all the time, like heat transfer coefficients. Some models, like those by El-Dessouky and others, include things like a set heat transfer area and vapor leaks. These models have been checked with real plant data and work well for guessing how the system will perform.

Tip: Engineers use both steady-state and dynamic models to help control and improve the process. Dynamic models are very helpful for showing how the system reacts to changes. This helps workers avoid problems and make the system work better.

Mathematical modeling is a strong tool for engineers. It helps make better designs, safer operation, and smarter control of multi-effect evaporators in many jobs.

A good system layout is very important for these machines. Engineers put the main parts, like vessels, heat exchangers, pumps, and pipes, in smart places. This helps everything flow well and makes fixing things easier. The effects are lined up from highest to lowest pressure. This lets vapor from one effect heat the next one. It saves a lot of energy.

Workers like a simple layout. They can watch each part and spot problems fast. Engineers put extra equipment, like condensers and vapor separators, close to the main vessels. This keeps pipes short and stops heat from escaping. Safety walkways give workers room to check and fix the machine.

A good layout also thinks about the future. Designers leave space for more effects or new parts. They make sure cleaning is easy and chemicals are safe to handle. By planning for easy access and smooth flow, the layout helps the machine work well for a long time.

How the vessels are set up changes how well the machine works. Engineers connect the vessels one after another. Each vessel runs at a lower pressure and temperature than the last. This setup lets vapor from one vessel heat the next one.

Aspect | Explanation |

|---|---|

Vessel Arrangement | Vessels are lined up in order, each with lower pressure and temperature. Vapor from one heats the next. |

Operational Efficiency | This setup uses heat again and again. It saves energy and makes the liquid thicker. |

Maintenance Impact | More vessels mean more parts to check and clean. Workers must look for scale and fix things often. |

Energy Optimization | Using vapor from one effect to heat the next saves steam and money. It is better for the planet. |

Fouling Sensitivity | Many vessels and heat surfaces can get dirty fast. Cleaning is needed to keep things working well. |

Workers must watch for scale and dirt. Many vessels and heat parts can get dirty quickly. Cleaning and checking often keeps the machine running well. Engineers add doors and openings to help with cleaning.

A smart vessel setup makes the machine work better and saves energy. By using heat again, the system needs less steam and costs less to run.

Putting all the parts together takes careful planning. Engineers use different ways to make sure the machine works its best:

Good heat control helps heat move well in every chamber.

Making the liquid flow evenly stops problems and waste.

Picking the right materials keeps heat moving and stops rust.

The system must work with other cooling machines if needed.

Engineers balance better performance with cost and how hard it is to build.

To save even more energy, engineers add special features:

Thermo-vapor compressors, feed preheaters, and split systems help use steam better.

Flash tanks catch extra heat and use it again.

Solar panels and wind power can help save regular energy.

Mixing different energy sources saves money and helps the environment.

Taking care of the machine is also very important. Workers clean often and use chemicals to stop scale. Sensors help find problems before they get big. Some places use solar heat or waste heat to save more energy.

A well-built system works well, saves energy, and lasts a long time. Smart design and new technology help workers reach their goals and protect the planet.

Putting together a multi-effect evaporator takes good planning and skilled work. Engineers and technicians follow steps to make sure the system is safe and works well.

Foundation Preparation

Workers first make a strong, flat base. The base must hold all the heavy parts. Concrete or steel is used for support.

Positioning of Major Components

Teams move big parts like vessels and heat exchangers into place. They use cranes or forklifts for lifting. Each part must match the layout plan.

Piping and Connections

Technicians put pipes between effects, pumps, and other equipment. Stainless steel pipes last a long time. Welders join pipes and check for leaks. All pipe joints must be safe and strong.

Mounting Pumps and Valves

Workers put pumps, valves, and meters in the right spots. Each pump must fit the liquid and flow needed. Valves should open and close easily.

Instrumentation Setup

Electricians and engineers add sensors, gauges, and control panels. They connect wires for checking temperature, pressure, and flow. Each tool must send correct data to the control system.

Insulation and Safety Features

Teams cover vessels and pipes with insulation. This keeps heat in and stops burns. Safety guards and shut-off switches are added for protection.

Tip: Always use the manufacturer’s instructions when building. Check all parts and connections before moving on.

Use safe lifting tools for heavy parts.

Keep the work area clean to stop accidents.

Label pipes and valves so they are easy to find.

Test each part for leaks before finishing.

Write down each step for future repairs.

Challenge | Solution |

|---|---|

Misaligned vessels | Use laser tools to line up parts |

Leaking joints | Fix or replace bad pipe connections |

Instrument errors | Set sensors right before starting |

Space constraints | Plan with 3D software to fit everything |

A well-built evaporator system runs smoothly and lasts a long time. Good installation stops breakdowns and saves money on repairs.

Engineers work to save energy in multi-effect evaporators. They use special ways to catch heat that might be lost. One way is vapor recompression. A compressor makes vapor hotter and under more pressure. This vapor then heats the next effect in the system. This means less new steam is needed. It also helps companies spend less money.

Another way is preheating the feed. The system uses hot liquid or vapor from later effects to warm up new liquid coming in. This step helps the liquid boil faster. Some factories use heat exchangers between effects. These help move heat better from one part to another. All these tricks help save energy and cut down on waste.

Tip: Check heat exchangers and compressors often. This keeps the system working well and stops energy loss.

Keeping the right temperature is very important for these machines. Each effect must be at the right temperature to boil and make vapor. Engineers use sensors and valves to watch and change temperatures quickly. They put sensors at important spots, like where liquid goes in and out.

If the temperature is too low, the liquid will not boil. If it is too high, some products can get ruined or burned. Automatic controls help keep temperatures safe. These controls change things fast if the feed or steam changes. Good temperature control also stops scale and dirt from building up.

Control Tool | Purpose |

|---|---|

Temperature sensors | Watch temperatures in each effect |

Control valves | Change steam and vapor flow |

Alarms | Warn if temperature is not safe |

Controlling the feed rate is needed for good operation. The feed rate is how much liquid goes into the machine. If too much goes in, the system cannot take out enough water. This makes the product too thin and lowers how well it works. If too little goes in, energy is wasted and the product gets too thick.

Engineers use flow meters and pumps to set the feed rate. They pick target numbers based on what the product needs and what the system can do. Workers watch the feed and change it when needed. Keeping the feed rate steady helps the machine work well and keeps the product good.

Note: Changing the feed rate too fast can make temperatures jump and lower efficiency. Slow changes help keep everything working smoothly.

Process automation helps multi-effect evaporators work better and safer. Engineers use automation to control things like temperature and flow. The system watches everything and makes changes right away. This keeps the machine working well.

Modern evaporators have sensors and control panels. These tools collect data from all parts of the system. The control system looks at this data and tells pumps, valves, and heaters what to do. If the feed rate changes, the system changes the steam flow. If the temperature drops, it opens a valve to add more steam. This fast action keeps the process steady.

Engineers use programmable logic controllers, or PLCs, for automation. PLCs run special programs that follow set rules. Operators can set target numbers for temperature and pressure. The PLC checks these numbers and makes changes when needed. This helps stop mistakes and lets workers do other jobs.

A normal automated evaporator system has:

Automation Feature | Function | Benefit |

|---|---|---|

Sensors | Measure temperature, pressure, flow | Real-time monitoring |

PLCs | Run control programs | Fast, accurate adjustments |

Human-Machine Interface (HMI) | Show system status and alarms | Easy for operators to use |

Data Logging | Record process data | Helps with troubleshooting |

Remote Access | Let engineers check and control from afar | Faster support and response |

Operators use the HMI to see alarms or warnings. If something goes wrong, the system can shut down or tell the team. This keeps the equipment and product safe.

Automated systems help save energy too. The control system can lower steam use when less is needed. It can also change the vacuum to save power. Automation helps companies spend less money and waste less.

Process automation makes it easier to follow safety rules. It helps keep the product good. Engineers use the data to find ways to make things better. Automation also helps new workers learn faster.

Tip: Update control software often and check sensors to get the best results.

Engineers and managers check capital costs before starting a project. Capital costs are the money needed for equipment, setup, and getting the site ready. The biggest costs come from vessels, heat exchangers, pumps, and control systems. Workers also build strong bases and add safety parts. The price of materials like stainless steel or special alloys can change. It depends on what goes into the system and how big it is.

A multi-effect evaporator needs more room and more pipes than a single-effect unit. Bigger systems with more effects cost more to build. But they save more energy as time goes on. Companies compare prices for different designs to find the best deal. They also look at automation and advanced controls. These can make the first price higher but help save money later.

Cost Item | Description | Impact on Budget |

|---|---|---|

Equipment | Vessels, heat exchangers, pumps | Largest share |

Installation | Labor, site prep, safety systems | Medium |

Materials | Stainless steel, alloys | Varies by design |

Automation | Sensors, PLCs, control panels | Adds up front cost |

Tip: Companies should get quotes from many suppliers to find the best price.

Operating costs are the money spent to run the evaporator every day. These costs include steam, electricity, water, chemicals, and workers. Steam and electricity are the biggest parts of the budget. Workers check pumps, valves, and sensors often to keep things working well.

Maintenance is also a big part of operating costs. Engineers plan cleaning to stop scale and keep heat moving well. If the system uses advanced automation, it may need special workers for repairs. The cost of chemicals for cleaning and water treatment can change. It depends on what goes in and what comes out.

A good system helps lower operating costs. Using energy recovery and automation saves money. Companies watch water use and waste to keep costs low.

Steam and electricity: Main energy costs

Labor: Operators and maintenance workers

Chemicals: Cleaning and water treatment

Repairs: Fixing pumps, valves, and sensors

Note: Training workers well helps stop mistakes and keeps costs down.

Return on investment (ROI) and payback period help companies see if buying a multi-effect evaporator is smart. ROI shows how much profit the system makes compared to its cost. Payback period tells how long it takes to get the money back.

Engineers figure out ROI by checking energy savings, less water use, and less waste. They compare these savings to the money spent on building and running the system. Most multi-effect evaporators pay for themselves in one to three years. Systems with more effects or better energy recovery can pay back even faster.

A high ROI means the system is a good buy. Companies use these numbers to show the project saves money. They also use payback data to plan upgrades later.

Metric | What It Means | Typical Value |

|---|---|---|

ROI | Profit vs. total cost | 15%–40% |

Payback Period | Time to recover investment | 1–3 years |

Companies should check ROI and payback numbers before making a final choice.

Cost optimization is very important for multi-effect evaporator projects. Engineers and managers use different ways to save money and keep the system working well. They focus on smart design, good operation, and regular cleaning.

Design Choices That Lower Costs

Engineers pick the right number of effects for each system. Too many effects cost more money. Too few effects waste steam and energy. They try to find the best balance. Using materials that do not rust helps stop repairs. Stainless steel lasts longer than normal steel. Modular designs make it easy to fix or upgrade parts.

Energy-Saving Techniques

Energy costs are a big part of running the machine. Teams use heat recovery to reuse energy from vapor and water. Preheating the feed with leftover heat lowers steam use. Mechanical vapor recompression (MVR) squeezes vapor to use it again for heat. These tricks help lower energy bills and make steam economy better.

Maintenance and Cleaning

Cleaning often stops scale and dirt from building up. Scale makes heat move slower and uses more energy. Workers plan cleaning times based on feed and how the system works. Anti-scaling chemicals help cut down on cleaning. Sensors help find problems early.

Automation and Controls

Automatic controls change steam, feed, and temperature fast. These systems react quickly when things change. Automation helps stop mistakes and keeps the process steady. Data logging lets managers watch how things work and find ways to improve.

Procurement and Supplier Selection

Managers check prices from many suppliers. They look for deals when buying lots of parts. Picking good vendors helps stop breakdowns. Using the same parts in many systems makes training and inventory easier.

Table: Cost Optimization Strategies

Strategy | Benefit | Example |

|---|---|---|

Modular design | Easy upgrades and repairs | Swappable tube bundles |

Heat recovery | Lower energy bills | Feed preheaters |

Automation | Stable operation | PLC-based controls |

Supplier selection | Lower purchase costs | Bulk orders |

Preventive maintenance | Fewer breakdowns | Scheduled cleaning |

Tip: Teams should check how the system runs every month. Small changes in feed or temperature can save a lot of money over time.

Cost optimization needs everyone to work together. Engineers, workers, and managers all help keep costs low and the system running well. Smart choices in design and operation help companies get the most from their multi-effect evaporators.

Multi-effect evaporators are very important in food factories. They help make fruit juice, milk, and tomato paste thicker. These machines take water out of liquids but do not change the taste or color. Many food companies use them so products last longer on shelves.

Engineers pick these systems because they save energy and keep food safe. The gentle heat in each step protects vitamins and flavors. Workers can change the process to get the right thickness every time. Companies also use evaporators to make syrups and drink concentrates. Some factories use them to get useful ingredients from waste.

Note: Food safety rules say temperature and cleanliness must be controlled. Multi-effect evaporators help meet these rules by making cleaning easy and keeping the process steady.

Sugar factories use evaporators to make sugar juice thick. The process starts with juice from sugar cane or sugar beets. Multi-effect evaporators take out most of the water. This leaves syrup ready for making sugar crystals.

These machines use steam again and again. Each step uses heat from the last one, so fuel costs go down. Operators can change the flow to match juice quality. The design helps stop scale and keeps syrup clean.

Step in Sugar Production | Role of Evaporators |

|---|---|

Juice extraction | Gets raw juice |

Evaporation | Takes out water, thickens juice |

Crystallization | Makes sugar crystals |

Sugar plants run evaporators for many hours during harvest. Cleaning often and using good materials keeps the system working well.

Pulp and paper mills use multi-effect evaporators for black liquor. Black liquor is a leftover liquid with water, chemicals, and wood solids. Evaporators take out water and make it thick enough to burn as fuel.

This helps paper mills save energy and reuse chemicals. Burning thick black liquor gives heat to the mill and cuts down waste. Engineers build these machines to handle sticky and harsh liquids. The evaporators must not get clogged and must work in tough places.

Operators watch the system closely to keep things safe. They use sensors to check temperature and flow. Good control stops blockages and keeps the mill working fast.

Tip: Using multi-effect evaporators in paper mills helps recycling and lowers harm to the environment.

Many factories must clean wastewater before letting it go. Multi-effect evaporators help companies follow these rules. They take water out of waste and leave less leftover waste. This makes it easier and cheaper to get rid of the rest.

Factories use these machines for wastewater from chemical plants, metal shops, and power plants. These systems can handle hard liquids with lots of salt, heavy metals, or strong chemicals. The design lets them use less energy than single-effect units. Each stage uses heat from the one before, so they save steam and money.

Engineers often pick these machines for zero liquid discharge systems. Zero liquid discharge means no liquid waste leaves the plant. The system gets clean water back and makes a solid or thick leftover. This helps companies avoid fines and keeps nature safe.

The main steps in a wastewater system with these machines are:

Pre-treatment: Workers take out oils, solids, or big pieces from the water.

Evaporation: The machine heats the water. Water turns to vapor and leaves thick waste behind.

Condensation: The vapor cools and turns into clean water. Companies can use this water again.

Residue Handling: The thick waste is collected for safe disposal or more treatment.

Note: Using multi-effect evaporators can cut waste by up to 95%. This saves money and helps meet green rules.

Engineers pick materials that do not rust for these machines. Wastewater can have acids, salts, or strong chemicals. Stainless steel and special metals last longer in these places. Workers watch temperature, pressure, and flow to keep things working well.

Some factories use computers to control the process. Sensors and panels help workers change settings fast. This keeps the machines working their best and stops problems.

Here is a table that shows where these machines are used:

Industry | Wastewater Type | Benefit of Evaporators |

|---|---|---|

Chemical Plants | Salty, toxic liquids | Reduces hazardous waste |

Metal Finishing | Heavy metals, acids | Recovers clean water |

Power Stations | Cooling tower blowdown | Cuts water discharge |

Textile Factories | Dye and salt waste | Lowers disposal costs |

Multi-effect evaporators are very important in cleaning wastewater today. They help companies save money, protect nature, and follow the law.

Engineers use computers to help design multi-effect evaporators. These tools let them see how the system will work before building it. CAD software helps teams make models of each part. They can watch how heat and liquid move inside the machine. Simulation programs like Aspen Plus or COMSOL Multiphysics test different designs. Engineers can change the number of effects or the size of tubes. They can also change how fast things flow. The software shows what happens when they make these changes.

Process simulation tools help fix problems too. If something goes wrong, engineers use the model to find out why. They can try solutions on the computer first. This saves time and money for the company. Many factories use digital twins. A digital twin is a computer copy of the real evaporator. It gets updates from sensors in the plant. Operators use the digital twin to watch the system and plan repairs.

Optimization algorithms help engineers run evaporators in the best way. These algorithms use math to test many choices quickly. They look for ways to use less energy or make better products. Some common algorithms are genetic algorithms, simulated annealing, and particle swarm optimization. Each one tries different settings for steam flow, feed rate, and temperature.

Engineers use these tools to pick the best settings. For example, an algorithm can find the right mix of energy savings and product quality. It can also help plan when to clean or fix the system. Optimization helps the evaporator work better and last longer. It also saves money by using less steam and fewer chemicals.

Tip: Using optimization algorithms can make steam economy better by up to 15%. This means big savings for large factories.

New materials have changed how engineers build evaporators. Stainless steel is still used a lot. But new alloys and coatings protect parts even more. Some plants use titanium or special plastics for parts that touch strong chemicals. These materials stop rust and last longer. Engineers also use coatings like Teflon to keep scale from sticking.

Advanced materials help the system handle higher heat and pressure. They also make cleaning easier for workers. Some new materials help heat move faster, so the evaporator works better. By picking the right materials, engineers can lower repair costs and make things safer.

Sustainability is now very important when picking materials. Many companies choose materials that last longer and can be recycled. This helps protect nature and supports green manufacturing.

Modern multi-effect evaporator design cares a lot about the environment. Engineers try to make these machines use less energy and make less waste. They use new ideas and better materials to save power and lower pollution.

Factories use energy recovery systems to catch heat that would be lost. This heat is used again, so plants need less steam and fuel. Using less fuel means fewer greenhouse gases go into the air. Some companies put up solar panels or use leftover heat from other machines. These steps help them use less oil and gas.

Saving water is also very important. Multi-effect evaporators can clean and reuse water from waste. This water can be used again in the factory or for washing. Less dirty water leaves the plant. This helps companies follow strict rules and keeps rivers and lakes safe.

Cutting down on waste is a big part of being green. Engineers pick materials that last a long time and do not rust. Stainless steel and special coatings help machines work for many years. When machines last longer, factories throw away less metal and plastic. Some factories also take useful chemicals out of waste. They can sell these chemicals or use them in other things.

Digital tools help make these machines even greener. Sensors and computers watch how much energy, water, and pollution the plant makes. Workers can find problems early and fix them fast. The data helps managers decide when to fix or upgrade machines.

Note: Many companies now write reports about how they help the environment. They show how much energy and water they save each year. Customers and investors like to see these numbers before they choose a company.

The table below lists some green practices for multi-effect evaporator systems:

Practice | Benefit |

|---|---|

Energy recovery | Uses less fuel and pollutes less |

Water recycling | Makes less waste and saves money |

Durable materials | Fewer parts need to be replaced |

Digital monitoring | Finds problems early |

Chemical recovery | Makes extra money and less waste |

By caring about the environment, engineers help companies save money and protect the earth. These actions also help follow the law and make customers trust the company.

Engineers use simple steps to design and build a multi-effect evaporator. They pick strong materials and plan where each part goes. Automation helps control the machine better. This equipment uses less energy and saves money. It is used in many different industries. Teams need to check how the machine works often. They should clean and fix it on a schedule. Trying new technology can help make the system even better.

Tip: Companies that train workers and use digital tools get better results. Their equipment also lasts longer.

A multi-effect evaporator takes water out of liquids. It uses steam in more than one step. This helps factories save energy and money. Engineers use these machines to make products thicker. They also use them to get clean water back.

When more effects are added, vapor from one step heats the next. This makes steam economy better. Factories need less new steam and save more energy. More effects mean more savings.

Food factories, sugar plants, paper mills, and water treatment plants use these machines a lot. These jobs need to make liquids thicker or get water back in a smart way.

Engineers pick stainless steel and special alloys for building. These materials do not rust and can handle chemicals. Using strong materials helps the machine last longer and need less fixing.

Operators watch temperature, pressure, and flow with sensors. They clean the machine often and look for leaks or scale. Automation helps keep things safe and warns workers if something is wrong.

Factories use these machines to save energy and reuse water. This lowers waste and helps follow green rules. Picking tough materials and using automation also helps protect the planet.

content is empty!