Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

In the modern industrial landscape, efficient and sustainable processing technologies are essential to meet stringent environmental regulations and growing economic demands. Multi-effect Evaporation & Crystallization stands out as a highly efficient and widely adopted technology for concentrating solutions, recovering valuable materials, and minimizing wastewater discharge in various industries. Zhejiang VNOR Environmental Protection Technology Co., Ltd., a leader in advanced evaporation solutions, offers cutting-edge Multi-effect Evaporation & Crystallization systems that enable companies to enhance productivity while reducing energy consumption and environmental footprint.

This comprehensive article delves deep into the concept of Multi-effect Evaporation & Crystallization, highlighting its working principles, technical advantages, applications, and the latest trends shaping its future. The content also aligns closely with the VNOR product offerings to provide a thorough understanding for professionals seeking effective evaporation and crystallization solutions.

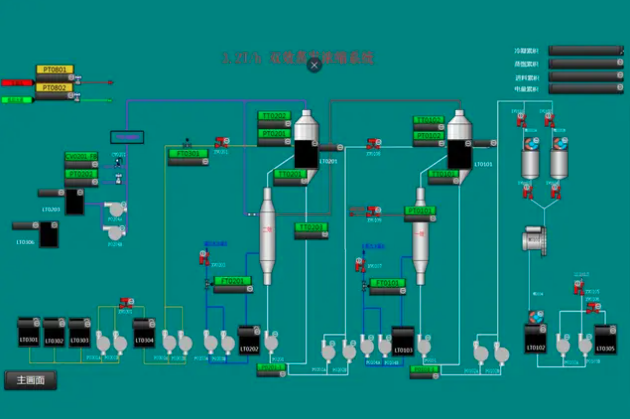

Multi-effect Evaporation & Crystallization is an integrated thermal separation technology that combines multiple-effect evaporation with crystallization processes to concentrate solutions and recover solids in the form of crystals. The core concept revolves around the efficient reuse of vapor energy generated from one evaporator effect to heat the next, which dramatically improves thermal efficiency and reduces steam consumption.

In crystallization, the concentrated solution reaches supersaturation conditions, promoting the formation of solid crystals that can be separated for product recovery or waste minimization. By coupling evaporation and crystallization, Multi-effect Evaporation & Crystallization systems provide a closed-loop approach to treat industrial liquids — especially those with high salt or chemical contents — enabling Zero Liquid Discharge or near-zero discharge operations.

Zhejiang VNOR specializes in providing robust and customized Multi-effect Evaporation & Crystallization equipment, optimizing energy usage, operational reliability, and environmental compliance.

The fundamental working principle of multi-effect evaporation involves cascading multiple evaporator vessels (effects), where each effect operates at progressively lower pressure and temperature. Steam is introduced into the first effect to heat the feed solution, causing it to evaporate. The vapor generated in the first effect is then reused as the heating medium for the second effect, and this cascade continues through subsequent effects.

This staged approach means the latent heat of vaporization is reused multiple times, drastically reducing steam consumption compared to single-effect evaporators.

In the Multi-effect Evaporation & Crystallization system, as the liquid is progressively concentrated across multiple effects, it eventually reaches a supersaturated state where dissolved solids start crystallizing. Crystallizers are often connected to the final effects or are incorporated as standalone units downstream to control crystal size and purity.

The crystals are then separated using filtration, centrifugation, or other solid-liquid separation methods, while the remaining liquid is recycled or further treated.

Feed Solution Input: Industrial wastewater, brine, or chemical solutions are fed into the first evaporator effect.

Heat Exchange & Evaporation: Steam heats the solution, causing evaporation.

Vapor Recycling: Generated vapor heats the subsequent effects in a cascade.

Concentration Increase: Each effect concentrates the solution by removing water.

Crystallization: Upon reaching supersaturation, crystals form.

Solid-Liquid Separation: Crystals are separated; concentrated brine or purified water is discharged or reused.

Multi-effect evaporation systems are designed to maximize energy utilization. By reusing steam heat across multiple stages (or “effects”), these systems achieve significant energy savings compared to single-effect systems. Each effect operates at a lower temperature than the previous one, allowing the steam from one effect to be used as the heat source for the next. This cascading effect reduces the overall energy consumption by up to 60-80%, making multi-effect evaporation highly efficient for large-scale industrial applications where energy costs are a major concern.

One of the key advantages of multi-effect evaporation is the ability to recover water and valuable salts/minerals through crystallization. This not only conserves resources but also allows for the extraction of valuable by-products, enhancing the overall efficiency and profitability of the process. For example, in the treatment of industrial wastewater, valuable salts and minerals can be recovered and reused, reducing waste and improving resource utilization.

Multi-effect evaporation systems support zero liquid discharge and minimize the release of harmful wastewater. This is particularly important in industries where environmental regulations are stringent, and the reduction of waste discharge is a priority. By minimizing wastewater, these systems contribute to sustainable practices and reduced environmental impact. zero liquid discharge systems ensure that all water is recovered and reused, leaving no liquid waste to be discharged into the environment.

Multi-effect evaporation systems are highly adaptable and can handle a wide range of feedstocks, including high salinity, corrosive, and high COD (Chemical Oxygen Demand) wastewater. This flexibility makes them suitable for various industrial applications, from chemical processing to food and beverage production. The ability to handle diverse feedstocks ensures that these systems can be tailored to meet the specific needs of different industries, making them a versatile solution for wastewater treatment and resource recovery.

Multi-effect evaporation systems have a simple structure with stable operation and low maintenance requirements. This ensures consistent performance over time, reducing downtime and maintenance costs. The robust design also means that these systems can operate reliably in challenging industrial environments. The use of high-quality materials and advanced engineering ensures that the systems can withstand harsh conditions, further enhancing their reliability and longevity.

While the initial investment for multi-effect evaporation systems may be higher compared to single-effect systems, the long-term savings in energy and operational costs make them a cost-effective choice for many industries. The reduced fuel and cooling water usage lead to lower operating costs over the system lifecycle. Additionally, the ability to recover valuable by-products and minimize waste discharge can provide additional economic benefits, making multi-effect evaporation systems a smart investment for sustainable and efficient industrial operations.

| Advantage | Explanation |

|---|---|

| Energy Efficiency | Multiple effects reuse steam heat, reducing energy consumption up to 60-80% compared to single-effect systems. |

| High Recovery Rates | Enables recovery of water and valuable salts/minerals through crystallization. |

| Environmental Impact | Supports zero liquid discharge and minimizes harmful wastewater release. |

| Process Flexibility | Suitable for diverse feedstocks, including high salinity, corrosive, and high COD wastewater. |

| Operational Reliability | Simple structure with stable operation and low maintenance requirements. |

| Cost-effectiveness | Reduced fuel and cooling water usage lead to lower operating costs over the system lifecycle. |

Multi-effect Evaporation & Crystallization systems are widely used across industries that require concentration, crystallization, and treatment of liquid waste streams. Some key sectors include:

Industrial processes generate high-salinity wastewater streams that cannot be discharged directly. Multi-effect Evaporation & Crystallization systems concentrate these wastewaters, recover salts as crystals, and recycle clean water — fulfilling zero liquid discharge requirements mandated by environmental regulations.

Concentration of active pharmaceutical ingredients, recovery of reagents, and crystallization of solids from liquid mixtures are common uses. The technology ensures product purity and minimizes solvent losses.

Concentrating fruit juices, sugar solutions, dairy products, and edible oils often involves evaporation. The crystallization step helps in sugar recovery and salt removal.

With the rapid growth of lithium-ion battery production, handling lithium brine and wastewater efficiently is critical. Multi-effect Evaporation & Crystallization technology supports lithium salt recovery, waste minimization, and resource recycling.

Recovery of valuable minerals such as sodium chloride, potassium salts, and magnesium salts is achieved by controlled crystallization, reducing waste and improving profitability.

Mechanical Vapor Recompression (MVR): Combining MVR technology with Multi-effect Evaporation & Crystallization allows further reduction of steam consumption by recompressing vapor instead of relying solely on fresh steam.

Thermal Vapor Recompression (TVR): Utilizes steam ejectors to increase vapor pressure, improving energy efficiency in multi-effect systems.

Heat Integration: Advanced process designs maximize heat recovery within plant utilities.

Smart control systems optimize operational parameters in real-time, improving yield and reducing downtime.

Predictive maintenance and IoT-enabled monitoring enhance reliability and reduce unplanned outages.

Use of corrosion-resistant materials such as titanium and duplex stainless steel extends equipment life in harsh chemical environments.

Modular and skid-mounted evaporators enable faster installation and scalability.

Greater emphasis on zero liquid discharge to comply with global environmental regulations.

Integration with renewable energy sources, such as solar thermal steam, to reduce carbon footprint.

A1: Multi-effect Evaporation and Crystallization is an integrated thermal separation technology that combines multiple-effect evaporation with crystallization processes. It is used to concentrate solutions and recover solids in the form of crystals, enabling Zero Liquid Discharge or near-zero discharge operations.

A2: Multi-effect Evaporation and Crystallization works by cascading multiple evaporator vessels (effects) where each effect operates at progressively lower pressure and temperature. Steam is introduced into the first effect to heat the feed solution, causing it to evaporate. The vapor generated in the first effect is then reused as the heating medium for the next effect, and this cascade continues through subsequent effects. As the solution becomes more concentrated, it reaches supersaturation, promoting the formation of solid crystals.

A3: The main advantages of Multi-effect Evaporation and Crystallization include energy efficiency, high recovery rates of water and valuable materials, minimal environmental impact, process flexibility, operational reliability, and cost-effectiveness over the system lifecycle.

A4: Multi-effect Evaporation and Crystallization achieves energy efficiency by reusing the latent heat of vaporization across multiple stages. This cascading effect reduces overall energy consumption by up to 60-80% compared to single-effect systems, making it highly efficient for large-scale industrial applications.

Multi-effect Evaporation & Crystallization is an indispensable technology in modern industrial processes requiring efficient liquid concentration and crystallization. The integration of multiple evaporation stages with crystallization allows for high energy efficiency, excellent resource recovery, and compliance with strict environmental regulations such as zero liquid discharge.

Zhejiang VNOR Environmental Protection Technology Co., Ltd. offers state-of-the-art Multi-effect Evaporation & Crystallization solutions that meet the demands of today’s industries through innovative design, customized engineering, and advanced operational control. Their multi-effect evaporators deliver superior performance, cost savings, and sustainability benefits that empower businesses to optimize production while reducing environmental impact. If you are looking for reliable and efficient Multi-effect Evaporation & Crystallization equipment to upgrade your process, Zhejiang VNOR offers comprehensive solutions backed by proven expertise and global service support. Contact VNOR to discover how their technology can help you achieve sustainable growth and operational excellence.