Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

As industries globally pursue zero liquid discharge, resource recovery, and sustainable manufacturing, Multi-effect Evaporation & Crystallization has become a key technology for efficiently concentrating solutions, recovering salts, and reducing wastewater volumes. However, operating Multi-effect Evaporation & Crystallization systems in a stable, energy-efficient, and cost-effective manner requires addressing various challenges.

ZheJiang VNOR Environmental Protection Technology Co., Ltd., a professional manufacturer specializing in Multi-effect Evaporation & Crystallization systems, has extensive expertise in designing and delivering high-performance, customizable evaporation and crystallization solutions for the chemical, pharmaceutical, lithium battery, and wastewater treatment industries. This comprehensive guide identifies the top operational challenges industries face with Multi-effect Evaporation & Crystallization and practical solutions based on advanced design and engineering insights, enabling manufacturers to maximize system efficiency, reliability, and lifecycle value.

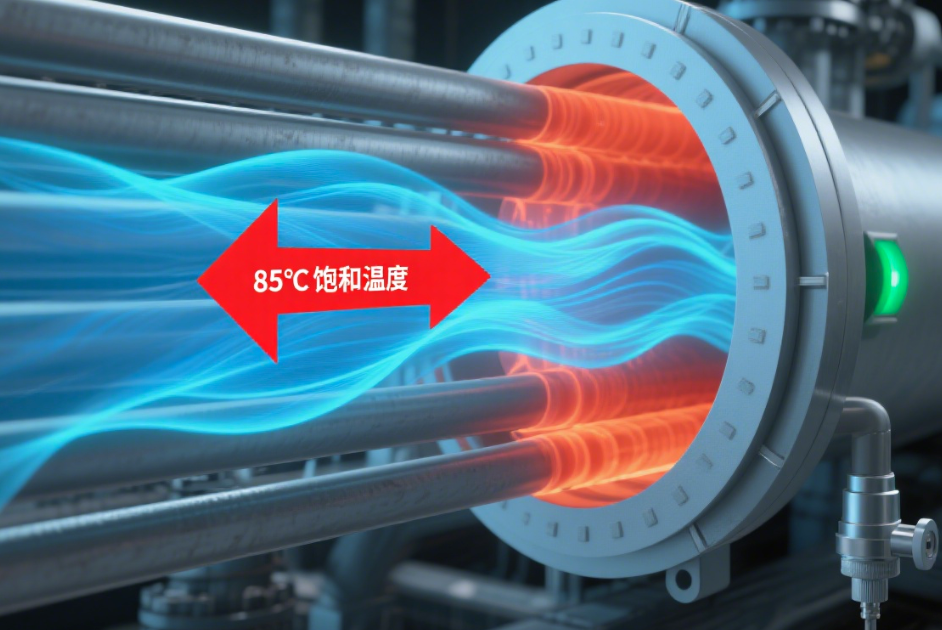

Multi-effect Evaporation & Crystallization involves the sequential evaporation of liquid feed across multiple effects under progressively lower pressures, utilizing the vapor generated in one effect to heat the next. This design significantly reduces steam consumption and operational costs. As the solution becomes concentrated, crystallization occurs, enabling the recovery of valuable salts and reducing the volume of liquid waste.

The core objectives of using Multi-effect Evaporation & Crystallization systems include:

High-efficiency liquid concentration.

Recovery of pure salts and minerals.

Supporting zero liquid discharge goals.

Lowering operational energy consumption.

Scaling, particularly from salts like calcium sulfate, calcium carbonate, and silica, can deposit on heat transfer surfaces within Multi-effect Evaporation & Crystallization systems. These deposits reduce heat transfer efficiency, increase steam consumption, and can cause unplanned shutdowns for cleaning. This issue is especially prevalent in systems handling high-salinity feed solutions.

While Multi-effect Evaporation & Crystallization is significantly more energy-efficient than single-effect systems, improper operation, poor design, or lack of process optimization can still lead to higher-than-expected energy consumption. Ensuring optimal energy use requires careful management of operating parameters and system design.

High-salinity or corrosive feed solutions can degrade materials within Multi-effect Evaporation & Crystallization systems, leading to equipment failure, leaks, and increased maintenance costs. This challenge is particularly acute in industries dealing with aggressive chemicals, such as the chemical and pharmaceutical sectors.

Uncontrolled nucleation and crystal growth during Multi-effect Evaporation & Crystallization can result in uneven crystal size distribution, affecting product quality and complicating downstream solid-liquid separation. Consistent crystal size is crucial for efficient separation and high product quality.

Variability in feed salinity, organic content, or pH can affect boiling point elevation, crystallization kinetics, and evaporation rates, leading to instability in Multi-effect Evaporation & Crystallization system performance. This challenge is common in industries with variable feed sources, such as wastewater treatment plants.

Frequent cleaning due to scaling, fouling, or corrosion increases downtime and maintenance costs in Multi-effect Evaporation & Crystallization operations. Reducing maintenance frequency while maintaining system efficiency is a key goal for operators.

Operating Multi-effect Evaporation & Crystallization systems to achieve zero liquid discharge while maintaining energy efficiency and stable crystallization requires advanced system design and process control. Achieving ZLD is a complex task that involves balancing energy use and crystallization efficiency.

Pre-treatment Systems: Implementing softening, filtration, and chemical dosing to remove hardness ions or silica before the feed enters Multi-effect Evaporation & Crystallization systems. This reduces the potential for scale formation on heat transfer surfaces. Pre-treatment can significantly extend the time between cleanings and maintain high heat transfer efficiency, which is crucial for energy-intensive processes.

Optimized Operating Conditions: Operating at temperatures and flow velocities that reduce supersaturation near heat transfer surfaces, minimizing the likelihood of scale deposition. By carefully managing these parameters, operators can prevent the conditions that typically lead to scaling, thereby maintaining consistent performance and reducing maintenance needs.

Periodic Cleaning: Implementing CIP (clean-in-place) systems to remove scale without dismantling equipment, reducing downtime and maintenance costs. CIP systems allow for efficient and effective cleaning, ensuring that heat transfer surfaces remain in optimal condition without the need for extensive manual intervention.

Effect Number Optimization: Choosing the optimal number of effects based on steam availability and energy-saving goals. This ensures that the system operates at peak efficiency without unnecessary complexity. The right balance of effects can significantly reduce energy consumption while maintaining high throughput and product quality.

Hybrid Integration with Mechanical Vapor Recompression: Further reducing steam consumption by compressing and reusing vapor within Multi-effect Evaporation & Crystallization systems. This hybrid approach combines the benefits of both technologies for maximum energy savings. MVR can be particularly effective in systems where steam costs are high or availability is limited.

Heat Recovery: Using condensate heat and integrating waste heat from other processes to preheat the feed or generate steam, reducing the overall thermal load. Heat recovery systems can capture and reuse energy that would otherwise be wasted, contributing to significant energy savings and improved sustainability.

ZheJiang VNOR Environmental Protection Technology Co., Ltd. utilizes high-grade stainless steel, duplex stainless steel, titanium, and corrosion-resistant alloys for Multi-effect Evaporation & Crystallization systems. These materials ensure long-term stable operation even with highly corrosive feeds, reducing maintenance and replacement costs. The choice of materials is critical for systems handling aggressive chemicals, as it directly impacts the durability and reliability of the equipment.

Seeding Techniques: Controlled seeding to manage crystal nucleation and growth, ensuring uniform crystal size distribution. This technique helps to prevent the formation of large, uneven crystals that can complicate downstream processing and reduce product quality.

Agitation Control: Ensuring uniform supersaturation to promote even crystal growth, improving product quality and downstream separation efficiency. Proper agitation can help to distribute crystals evenly throughout the solution, preventing clumping and ensuring consistent growth.

Temperature Gradient Management: Controlling temperature profiles across effects to achieve consistent crystallization, enhancing overall system performance. By carefully managing temperature gradients, operators can optimize the crystallization process and ensure high-quality product output.

Automated monitoring of key parameters such as temperature, pressure, flow rates, and concentration in Multi-effect Evaporation & Crystallization systems enables real-time adjustments to optimize system stability and efficiency. Advanced control algorithms can detect and correct deviations, ensuring consistent operation. Automation not only improves efficiency but also reduces the risk of human error and enhances overall process reliability.

ZheJiang VNOR Environmental Protection Technology Co., Ltd. designs Multi-effect Evaporation & Crystallization systems customized to handle fluctuating feed compositions through robust control strategies and flexible operational parameters. This ensures stable performance even with variable feed sources. Customized systems can adapt to changing feed conditions, maintaining high efficiency and product quality regardless of input variations.

Combining Multi-effect Evaporation & Crystallization with crystallizers and solid-liquid separation systems allows stable zero liquid discharge operation while maximizing water recovery and salt purity. This integrated approach ensures sustainable and efficient resource management. Achieving ZLD is a key goal for many industries, and a well-designed system can significantly reduce environmental impact while recovering valuable resources.

A: This technology is crucial for industries aiming to achieve zero liquid discharge (ZLD), recover valuable resources, and reduce wastewater volumes. It offers high-efficiency liquid concentration, supports sustainable manufacturing, and lowers operational energy consumption.

A: Industries such as chemical, pharmaceutical, lithium battery, and wastewater treatment benefit significantly from this technology. These sectors often require efficient liquid concentration and resource recovery while minimizing environmental impact.

A: Scaling, particularly from salts like calcium sulfate and silica, can deposit on heat transfer surfaces, reducing heat transfer efficiency, increasing steam consumption, and causing unplanned shutdowns for cleaning. This issue is especially prevalent in systems handling high-salinity feed solutions.

A: Energy consumption can be optimized by choosing the optimal number of effects, integrating Mechanical Vapor Recompression (MVR) to compress and reuse vapor, and using heat recovery systems to preheat the feed or generate steam.

Operating Multi-effect Evaporation & Crystallization systems effectively requires addressing challenges related to scaling, energy consumption, corrosion, crystallization quality, feed variability, and maintenance. Through advanced engineering, material selection, automated process control, and customized system design, industries can achieve stable, efficient, and cost-effective Multi-effect Evaporation & Crystallization operations. If your facility aims to enhance operational efficiency while addressing the challenges of Multi-effect Evaporation & Crystallization, contact ZheJiang VNOR Environmental Protection Technology Co., Ltd. today to learn how their advanced systems can transform your wastewater treatment, resource recovery, and concentration processes.